Nau'in Simintin Ƙarfe

Nau'in Simintin Ƙarfe

Wannan babin zai tattauna nau'ikan simintin ƙarfe iri-iri.

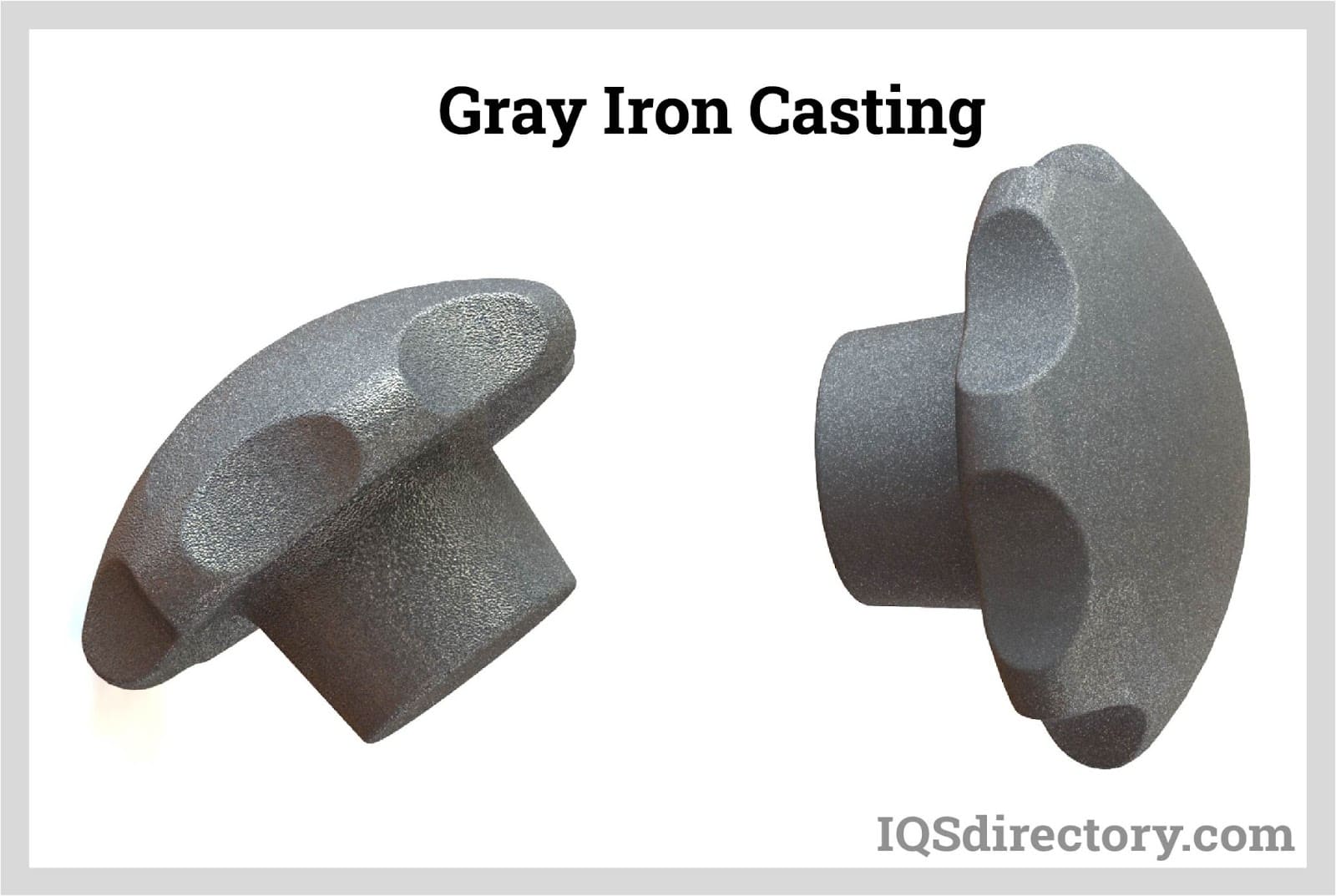

Grey Iron Casting

Halin simintin simintin simintin launin toka shine ƙirar microstructure mai hoto, wanda zai iya haifar da karyewa ga kayan kuma yana da launin toka. Wannan nau'in simintin ƙarfe ne da aka fi amfani da shi da kuma kayan da aka saba amfani da shi bisa nauyi. Yawancin simintin ƙarfe na launin toka suna da bazuwar sinadarai na kashi 2.5 zuwa kashi 4 cikin ɗari na carbon, kashi 1 zuwa 3 bisa ɗari na silicone kuma sauran abubuwan ƙarfe ne.

Irin wannan simintin ƙarfe yana da ƙarancin ƙarfi da ƙarancin juriya idan aka kwatanta da ƙarfe. Ƙarfinsa na matsawa yana kama da ƙananan ƙarfe da matsakaici na carbon.

Duk waɗannan kaddarorin injinan ana sarrafa su ta hanyar sifar flake na graphite da girman flakes ɗin graphite, waɗanda ke cikin ƙananan ƙirar ƙarfe na simintin toka.

Farar Simintin Ƙarfe

Irin wannan baƙin ƙarfe yana da fastoci da suka karye waɗanda suke fari ne saboda kasancewar ƙarfen carbide hazo mai suna siminti. Carbon da ke ƙunshe a cikin farin simintin ƙarfe na simintin gyare-gyare yana fitowa daga narkewa kamar yadda ya hadu da tsayayyen lokaci siminti maimakon a matsayin graphite. Ana samun wannan tare da ƙananan abun ciki na silicon azaman wakili mai zane da saurin sanyaya da aka kawo. Bayan wannan hazo, siminti ya zama babban barbashi.

A lokacin hazo na carbide baƙin ƙarfe, hazo yana zana carbon daga narke na asali, don haka yana motsa cakuda zuwa wanda yake kusa da eutectic. Sauran lokaci yana rage baƙin ƙarfe zuwa carbon austenite, wanda ke canzawa zuwa martensite da zarar an sanyaya.

Waɗannan ƙunshe da eutectic carbides sun yi girma da yawa don ba da fa'idar taurin hazo. A wasu karafa za a iya samun ƙaramar siminti da yawa waɗanda za su iya ɗaukar nakasar filastik ta hanyar hana motsin ɓarna ta cikin matrix ɗin ƙarfe mai tsabta. Suna da fa'ida yayin da suke ƙara yawan taurin simintin ƙarfe kawai saboda taurin kansu da juzu'i. Wannan yana haifar da babban taurin ana iya kusantar da ƙa'idar gaurayawan.

Ana ba da wannan taurin a farashin tauri a kowane hali. Farin simintin ƙarfe na iya zama gabaɗaya azaman siminti, tunda carbide ya ƙunshi babban juzu'i na kayan. Farin ƙarfe yana da ƙarfi sosai don a yi amfani da shi a cikin abubuwan da aka gyara, amma saboda taurinsa mai kyau, juriya ga abrasion, da ƙarancin farashi, ana iya amfani da shi azaman lalacewa na famfunan slurry.

Yana da wuya a sanyaya simintin gyare-gyare mai kauri a cikin sauri wanda ya isa ya ƙarfafa narkewa kamar farin ƙarfe na simintin gyare-gyare, duk da haka ana iya sanya sanyi mai sauri don amfani da shi don ƙarfafa jahannama na farin simintin ƙarfe kuma bayan wannan zai zama ragowarsa. sanyi a hankali a hankali don haka samar da ainihin baƙin ƙarfe mai launin toka. Ana kiran wannan simintin simintin gyaran kafa mai sanyi, kuma yana ƙunshe da fa'idodin samun saman ƙasa mai ƙarfi amma tare da mafi tsananin ciki.

Maɗaukakin farin ƙarfe na ƙarfe na chromium yana da ikon barin babban simintin simintin gyare-gyare na kusan tan 10 don zama simintin yashi. Wannan shi ne saboda gaskiyar cewa chromium yana rage yawan sanyaya da ake buƙata don samar da carbide ta hanyar mafi girman kauri na kayan. Carbides tare da kyakkyawan juriya na abrasion kuma ana samar da su ta abubuwan chromium.

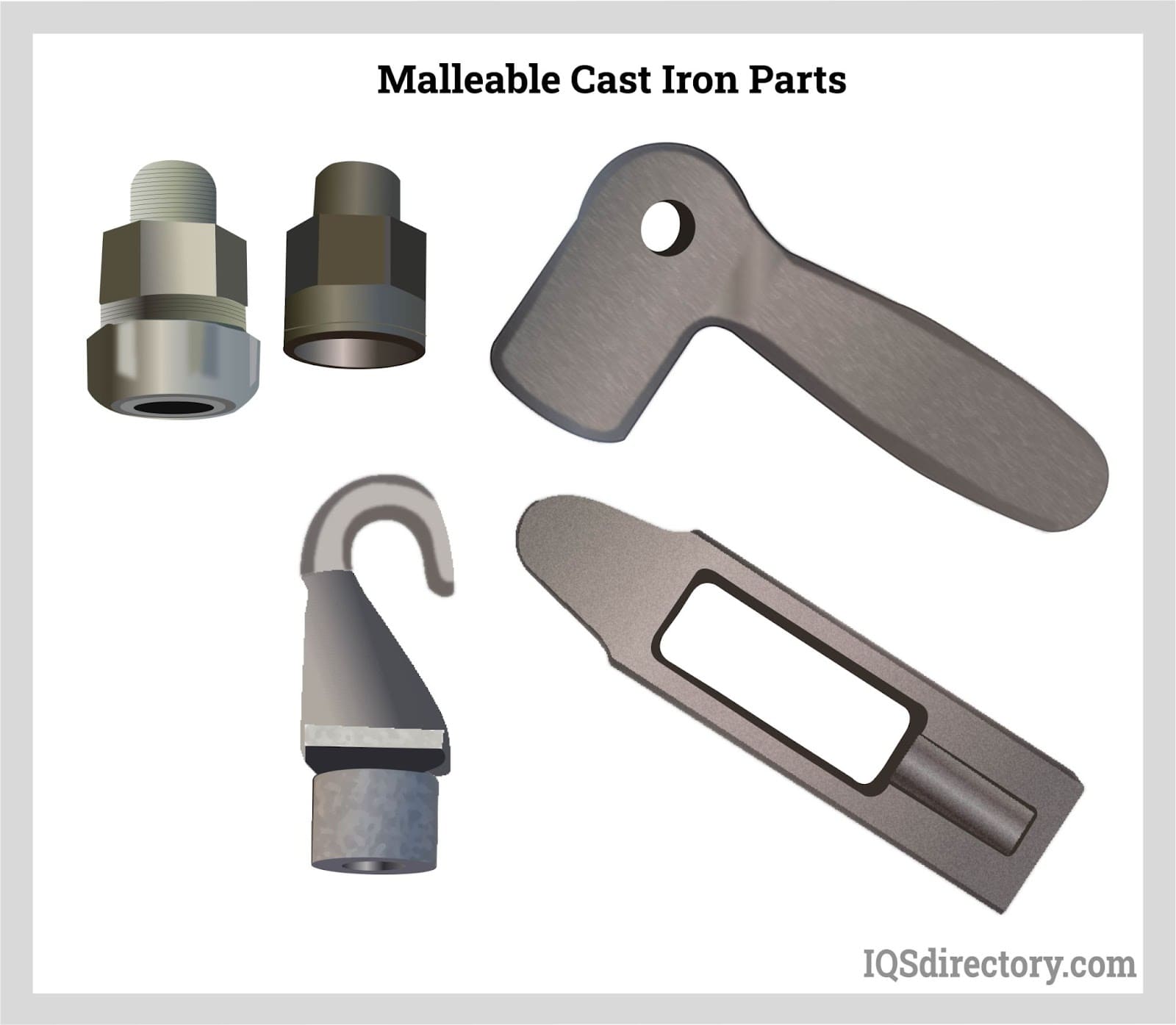

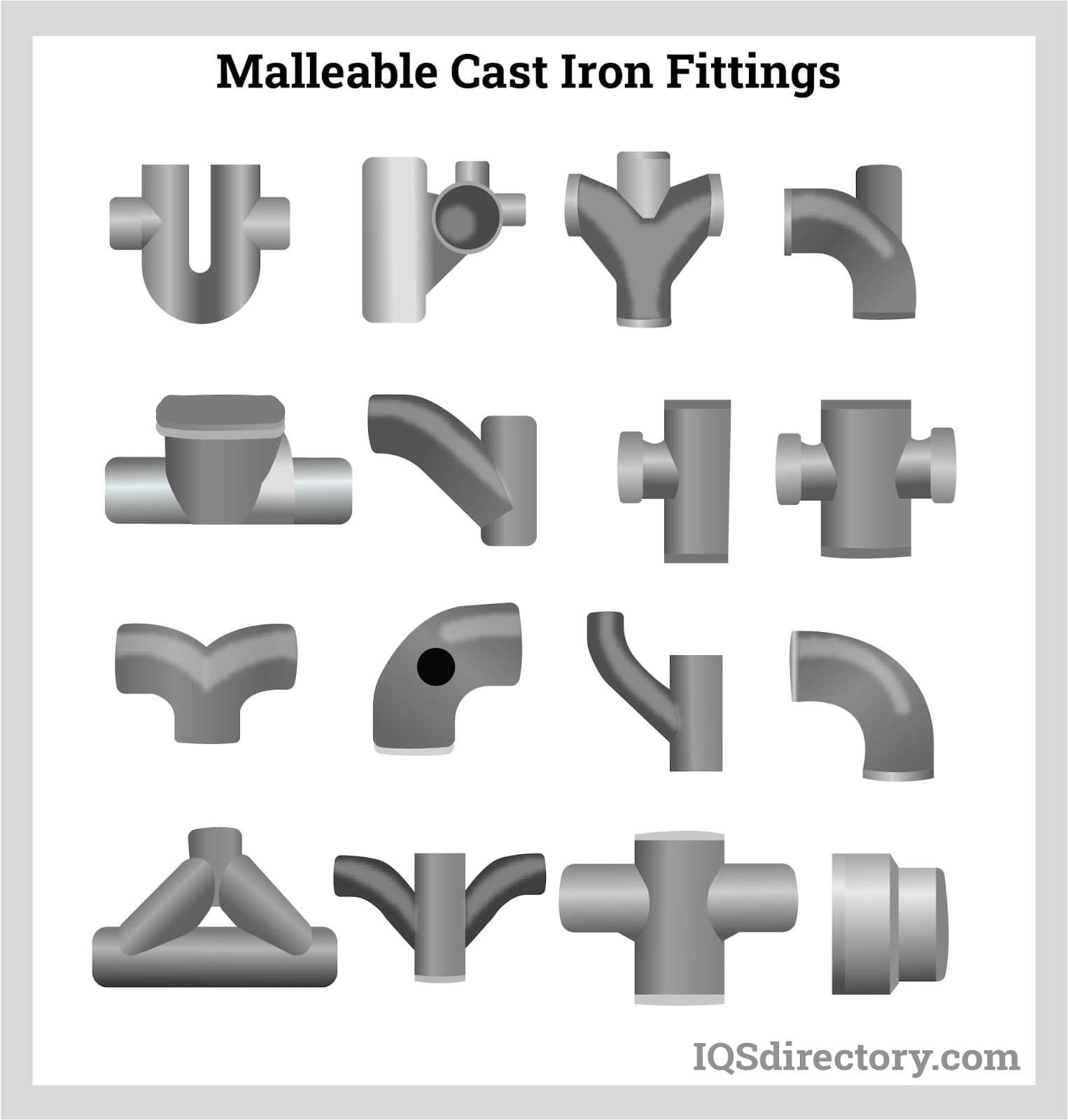

Ƙarfe mai yuwuwa

Simintin simintin gyare-gyare yana farawa azaman simintin ƙarfe na farin ƙarfe, sa'an nan kuma ana kula da zafi a yanayin zafi kamar 950 ° C na kwana biyu ko ɗaya, sannan a sanyaya shi tsawon lokaci guda.

Carbon da ke cikin carbide baƙin ƙarfe sannan ya koma graphite da ferrite da carbon saboda wannan tsarin dumama da sanyaya. Wannan ƙananan tsari ne, amma yana ba da damar tashin hankali na saman don canza graphite zuwa barbashi spheroidal maimakon flakes.

Spheroids suna da ɗan gajeren gajere kuma suna da nisa daga juna saboda ƙarancin yanayin yanayin su. Har ila yau, suna ƙunshe da ƙananan ɓangaren giciye, fashewa da kuma photon. Sabanin flakes, suna ƙunshe da iyakoki mara kyau waɗanda ke shiga cikin rage matsalolin damuwa waɗanda ke samuwa a cikin baƙin ƙarfe mai launin toka. Gabaɗaya, kaddarorin da aka haɗa a cikin simintin simintin gyare-gyaren malleable sun fi kama da na ƙarfe wanda ke da laushi a yanayi.

Simintin Ƙarfe

Wani lokaci ana kiransa ƙarfen simintin nodular, wannan simintin ƙarfe yana da graphite ɗinsa a cikin sigar ƙananan nodules, tare da graphite yana da nau'i na yadudduka waɗanda ke da hankali kuma don haka suna samar da nodules. Saboda wannan, Properties naductile jefa baƙin ƙarfesu ne na wani spongy karfe wanda ba shi da danniya taro sakamako samar da flakes na graphite.

Matsakaicin adadin carbon da ke ƙunshe yana kusan kashi 3 zuwa kashi 4 cikin ɗari, kuma na silicon yana kusa da kashi 1.8 zuwa kashi 2.8. Ƙananan adadin kashi 0.02 zuwa kashi 0.1 na magnesium, kuma kawai kashi 0.02 zuwa kashi 0.04 cikin ɗari cerium idan aka ƙara zuwa waɗannan allunan yana rage yawan ƙimar da hazo mai graphite ke girma ta hanyar haɗin kai zuwa gefuna na graphite.

Carbon na iya samun damar rarrabuwa a matsayin ɓangarorin spheroidal kamar yadda kayan ke ƙarfafawa, saboda kulawar wasu abubuwa da kuma lokacin da ya dace yayin aiwatarwa. Abubuwan da aka samu sun yi kama da ƙarfe na simintin gyare-gyare, amma ana iya jefa sassan da sassan da suka fi girma.

Aloying Elements

Ana canza kaddarorin simintin simintin gyare-gyare kuma ana ƙara su a cikin abubuwa masu haɗawa daban-daban ko alloli a cikin simintin ƙarfe. A cikin layi tare da carbon shine sinadarin silicon saboda yana da ikon tilasta carbon daga mafita. Karamin kaso na silicon ba zai iya cika wannan cikar ba saboda yana ba da damar carbon ya kasance a cikin maganin, don haka samar da carbide baƙin ƙarfe kuma yana samar da farin simintin ƙarfe.

Kashi mafi girma ko maida hankali na silicon yana iya tilasta carbon daga cikin maganin sannan ya samar da graphite kuma ya samar da baƙin ƙarfe mai launin toka. Sauran abubuwan da ba a lura da su ba sun haɗa da manganese, chromium, titanium sannan vanadium. Wadannan suna hana silicon, suna kuma inganta riƙewar carbon kuma ta haka ne ma samuwar carbides. Nickel da jan ƙarfe suna da fa'ida yayin da suke ƙara ƙarfi da injina, amma ba za su iya canza adadin carbon da aka samu ba.

Carbon da ke cikin nau'i na graphite yana haifar da baƙin ƙarfe mai laushi, don haka rage tasirin raguwa, rage ƙarfin da rage yawan nauyin da ke ciki. Sulfur galibi gurɓataccen abu ne idan an ɗauke shi, kuma yana samar da ƙarfe sulfide wanda ke hana samuwar graphite kuma yana ƙara tauri.

Rashin lahani da sulfur ke haifarwa shine cewa yana sanya narkakkar baƙin ƙarfe dan ƙoƙon gani, wanda ke haifar da lahani. Don kulawa da kawar da tasirin sulfur, an ƙara manganese zuwa maganin. Ana yin haka ne domin idan aka haɗa su biyun sai su zama manganese sulfide maimakon ƙarfe sulfide. Sakamakon sulfide na manganese ya fi narke wuta kuma yana ƙoƙarin yin shawagi daga cikin narke kuma ya shiga cikin slag.

Matsakaicin adadin manganese da ake buƙata don soke tasirin sulfur shine raka'a 1.7 na abun ciki na sulfur da ƙarin kashi 0.3 da aka ƙara akan sama. Ƙara fiye da wannan adadin manganese yana haifar da samuwar manganese carbide kuma wannan yana ƙara taurin zuciya da sanyi sai dai a cikin baƙin ƙarfe mai launin toka inda har kashi 1 cikin dari na manganese zai iya ƙara ƙarfi da yawa da ke cikin. Nickel yana ɗaya daga cikin abubuwan haɗakarwa na gabaɗaya saboda yana da dabi'ar tace pearlite da tsarin graphite, don haka inganta tauri, kuma yana fitar da bambancin taurin tsakanin kauri na sashe.

Ana ƙara Chromium a cikin ƙananan kuɗi don rage graphite kyauta da kuma samar da sanyi. Wannan saboda chromium shine mai ƙarfi carbide stabilizer, kuma a wasu lokuta yana iya aiki tare da nickel. Don chromium kuma, ana iya ƙara ƙaramin adadin kwano. Ana ƙara jan ƙarfe a cikin ladle ko tanderu akan tsari na kashi 0.5 zuwa kashi 2.5 don samun raguwar sanyi, tace graphite, da haɓakar ruwa. Hakanan za'a iya ƙara molybdenum a cikin tsari na kashi 0.3 zuwa kashi ɗaya cikin ɗari don ƙara sanyi, tace graphite, da kuma tace tsarin lu'u-lu'u.

Yawancin lokaci ana ƙara aiki tare da nickel, jan ƙarfe, da chromium don samar da ƙarfe mai ƙarfi. Ana ƙara sinadarin titanium don yin aiki azaman degasser da deoxidizer, kuma yana ƙara yawan ruwa. Matsakaicin kashi 0.15 zuwa kashi 0.5 na sinadarin vanadium ana ƙara su zuwa ƙarfen simintin gyare-gyare da kuma taimakawa wajen daidaita siminti, don ƙara tauri da tsayayya da lalacewa da tasirin zafi.

Zirconium yana taimakawa wajen samar da graphite kuma ana ƙara shi da kusan kashi 0.1 zuwa kashi 0.3. Wannan sinadari kuma yana taimakawa a cikin deoxidizing da ƙara yawan ruwa. A cikin baƙin ƙarfe maras nauyi, don ƙara yawan adadin siliki, ana zuba bismuth a cikin ma'aunin kashi 0.002 zuwa kashi 0.01. A cikin farin ƙarfe, ana ƙara sinadarin boron, wanda ke taimakawa wajen samar da baƙin ƙarfe wanda ba zai iya lalacewa ba, kuma yana rage tasirin bismuth.