Plhaub Pwm Casting txheej txheem

Plhaub pwm casting yog txheej txheem hlau casting zoo ib yam li cov xuab zeb casting, nyob rau hauv uas molten hlau yog poured rau hauv ib tug expendable pwm. Txawm li cas los xij, hauv plhaub pwm casting, pwm yog lub plhaub nyias-walled tsim los ntawm kev siv cov xuab zeb-resin sib tov nyob ib ncig ntawm tus qauv. Cov qauv, ib daim hlau nyob rau hauv cov duab ntawm qhov xav tau, yog rov qab siv los ua ntau lub plhaub pwm. Ib tug qauv reusable tso cai rau ntau lawm tus nqi, thaum cov pwm pov tseg ua rau complex geometries yuav cam khwb cia. Plhaub pwm casting yuav tsum tau siv cov qauv hlau, qhov cub, xuab zeb-resin sib tov, lub thawv pov tseg, thiab cov hlau molten.

Plhaub pwm casting tso cai rau siv ob qho tib si ferrous thiab non-ferrous hlau, feem ntau yog siv cam khwb cia hlau, carbon steel, alloy steel, stainless hlau, aluminium alloys, thiab tooj liab alloys. Yam khoom yog qhov me me-rau-nruab nrab ntawm qhov loj thiab xav tau qhov tseeb, xws li iav vaj tse, lub tog raj kheej taub hau, txuas pas nrig, thiab caj npab npab.

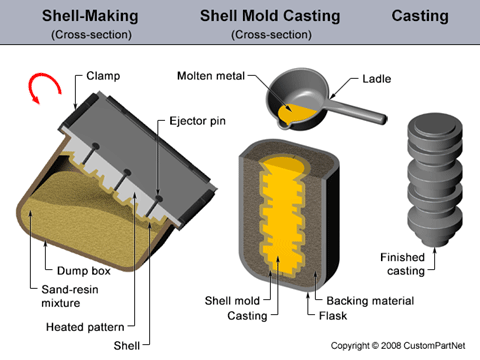

Lub plhaub molding txheej txheem muaj cov kauj ruam hauv qab no:

- Qauv creation- Ib qho qauv ntawm ob daim hlau yog tsim nyob rau hauv cov duab ntawm qhov xav tau, feem ntau yog los ntawm hlau lossis hlau. Lwm cov ntaub ntawv siv qee zaum, xws li txhuas rau cov khoom ntim qis lossis graphite rau cov khoom siv rov ua dua tshiab.

- Pwm creation- Ua ntej, txhua tus qauv ib nrab yog rhuab mus rau 175-370 ° C (350-700 ° F) thiab coated nrog roj nplua nyeem los pab tshem tawm. Tom ntej no, cov qauv rhuab yog clamped rau ib lub thawv pov tseg, uas muaj cov sib tov ntawm xuab zeb thiab resin binder. Lub thawv pov tseg yog inverted, tso cai rau cov xuab zeb-resin sib tov rau txheej txheej. Cov qauv rhuab ib nrab kho qhov sib tov, uas tam sim no tsim lub plhaub nyob ib ncig ntawm tus qauv. Txhua tus qauv ib nrab thiab ib puag ncig lub plhaub tau kho kom tiav hauv qhov cub thiab tom qab ntawd lub plhaub tau tawm ntawm tus qauv.

- Pwm sib dhos- Ob lub plhaub ib nrab tau koom ua ke thiab ruaj ntseg clamped los ua kom tiav lub plhaub pwm. Yog tias xav tau cov cores, lawv tau muab tso ua ntej kaw lub pwm. Tom qab ntawd lub plhaub pwm yog muab tso rau hauv lub hwj thiab txhawb nqa los ntawm cov khoom siv rov qab.

- Ncuav- Cov pwm yog ruaj khov ua ke thaum lub molten hlau yog poured los ntawm ib tug ladle rau hauv lub rooj vag system thiab nyob rau hauv lub pwm kab noj hniav.

- Txias- Tom qab cov pwm tau ntim lawm, cov hlau molten raug tso cai kom txias thiab khov rau hauv cov duab ntawm qhov kawg casting.

- Kev tshem tawm Casting- Tom qab cov hlau molten tau txias, cov pwm tuaj yeem tawg thiab tshem tawm. Trimming thiab tu cov txheej txheem yuav tsum tau tshem tawm cov hlau ntau dhau los ntawm cov khoom noj thiab cov xuab zeb los ntawm pwm.

Muaj peev xwm

| ||||||||||||||||||||||||||||||||||||