Cov txheej txheem ntawm CNC machining cov khoom

Hauv qhov kev nkag siab no, ntau lub rooj cob qhia uas muaj kev pabcuam machining rau qhov chaw tau tsim ib txoj hauv kev ua haujlwm uas lav tau cov txiaj ntsig zoo raws li qhov sib xws. Uas tau hais tias, txawm hais tias txhua qhov chaw tsim khoom muaj nws tus kheej cov txheej txheem, qee cov kauj ruam hauv kev ua haujlwm machining yog yam tsis muaj kev zam, tsis hais txog qhov yuav tsum tau ua.

Hauv kab lus no, nrhiav cov kauj ruam tseem ceeb ntawm machining.

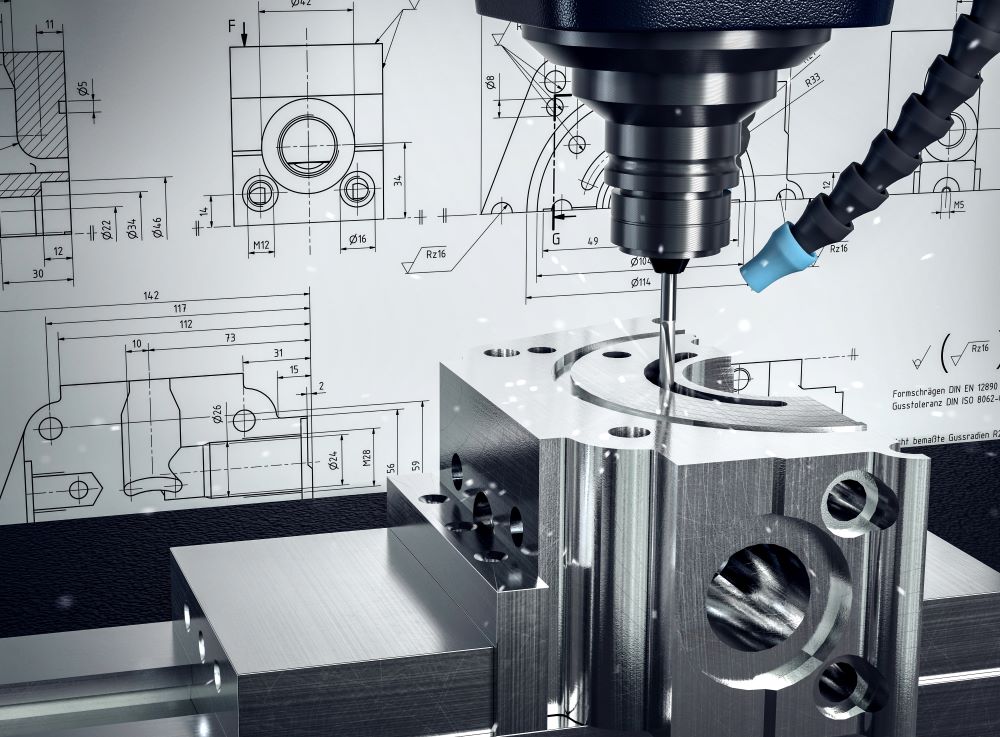

Theem 1 - Kev tshuaj xyuas thiab kev pom zoo ntawm kev kos duab ntawm lub workpiece

Ua ntej pib lub machining ntawm ib feem, qhov zoo ntawm cov phiaj xwm lossis kev kos duab uas cov tshuab ua haujlwm yuav siv los ua lub hauv paus rau lawv txoj haujlwm yog qhov tseem ceeb.

Yog li ntawd, lub tshuab khw muab rau txoj hauj lwm yuav tsum validate, nrog rau cov neeg siv, ntau yam ntaub ntawv uas muaj nyob rau hauv lub technical drawings muab rau lawv. Lawv yuav tsum xyuas kom meej tias qhov ntev, cov duab, cov ntaub ntawv los yog qib ntawm precision xaiv rau txhua feem ntawm lub workpiece yuav tsum machined yog qhia meej thiab siv tau.

Hauv kev lag luam xws li precision machining, qhov kev nkag siab me ntsis lossis kev ua yuam kev tuaj yeem muaj qhov cuam tshuam loj rau qhov zoo ntawm qhov kawg tshwm sim. Ntxiv mus, cov cuab yeej thiab cov txheej txheem machining yuav raug siv los tsim ib feem yuav raug xaiv raws li qhov sib txawv no.

Theem 2 – Modeling los yog prototyping qhov yuav tsum tau tsim

Thaum tsim machined qhov chaw nrog cov duab complex, computer modeling los yog prototyping ntawm cov khoom no yuav pab tau. Cov kauj ruam no muab ib lub tswv yim zoo ntawm qhov kawg tshwm sim ntawm qhov yuav tsum tau machined.

Piv txwv li, thaummanufacturing custom iav, 3D saib ntawm ib feem thiab nws cov ntsej muag sib txawv tuaj yeem tau txais los ntawm kev nkag mus rau ntau yam ntaub ntawv rau hauv software siab heev.

Theem 3 – Xaiv cov txheej txheem machining yuav siv

Nyob ntawm cov khoom xaiv rau ib feem thiab nws cov degree ntawm complexity, qee cov txheej txheem machining yuav ua tau zoo dua li lwm tus hauv kev ua tiav qhov xav tau.

Ntau yamindustrial machining txheej txheemtuaj yeem siv los ntawm machinists:

- Milling

- tho txawv

- Mortising

- Drilling

- Kev kho

- thiab ntau lwm tus.

Theem 4 – Xaiv lub tshuab zoo siv

Phau ntawv los yog CNCtshuab cuab yeejuas yuav siv los tsim ib feem tshiab yuav tsum tau xaiv raws li theem ntawm complexity ntawm ib feem thiab cov degree ntawm precision uas yuav tsum tau ua kom tiav.

Piv txwv li, cov cuab yeej siv computer xws liCNC tho txawv tshuabtej zaum yuav xav tau. Hom tshuab no tuaj yeem ua tau zoo heev thaum ib feem yuav tsum tau ua ntau daim ntawv luam.

Qee zaum, koj tseem yuav tau ua haujlwm nrog lub tshuab uas muaj peev xwmua haujlwm ntawm 5 axes sib txawv es tsis yog 3, los yog muaj peev xwmmachining qhov chaw uas tsis yog tus qauv qhov ntev.

Theem 5 - Machining ntawm ib feem los ntawm machinist

Yog tias tag nrho cov kauj ruam ua ntej tau ua tiav lawm, lub workpiece yuav tsum tau machined yam tsis muaj teeb meem.

Tus kws kho tshuab yuav tuaj yeem siv phau ntawv thiab cov cuab yeej siv computer los tsim ib feem los ntawm ib qho thaiv ntawm cov khoom xaiv thiabmuab nws lub siab xav ua tiav.

Theem 6 – Kev tswj kom zoo

Kev tswj xyuas kom zoo yog qhov tseem ceeb rau kev ua kom ntseeg tau tias qhov chaw tsim khoom sib raug rau txhua qhov kev hwm nrog tus thawj specifications ntawm lub tshuab nws yog ib tug neeg kho tshuab feem ntawm.

Qhov no yog ua tiav nrog kev pab los ntawm ntau yam kev ntsuam xyuas qhov chaw tuaj yeem raug thiabntsuas cov cuab yeejzoo li amicrometer.

Ntawm SayheyCasting, peb cov tshuab tshuab ua haujlwm nruj heev ntawm txhua theem ntawm cov txheej txheem machining

Hauv cov ntsiab lus, yog tias koj tab tom nrhiav rau lub khw muag khoom kom outsource qhov chaw tsim khoom, xyuas kom tseeb tias nws cov neeg ua haujlwm ua haujlwm hauv cov txheej txheem thiab txheej txheem. Cov txheej txheem tsim khoom uas ua raws li cov txheej txheem machining feem ntau yuav ua kom muaj tseeb.

Ntawm Sayheycasting, peb muab koj ntau yam kev pabcuam machining kom tau raws li tag nrho koj cov kev xav tau machined. Tsis muaj teeb meem dab tsi koj xav tau, peb yuav tsim cov qauv zoo tshaj plaws hauv kev lag luam, lav!