Hom Hlau Castings

Hom Hlau Castings

Tshooj no yuav tham txog ntau hom hlau castings.

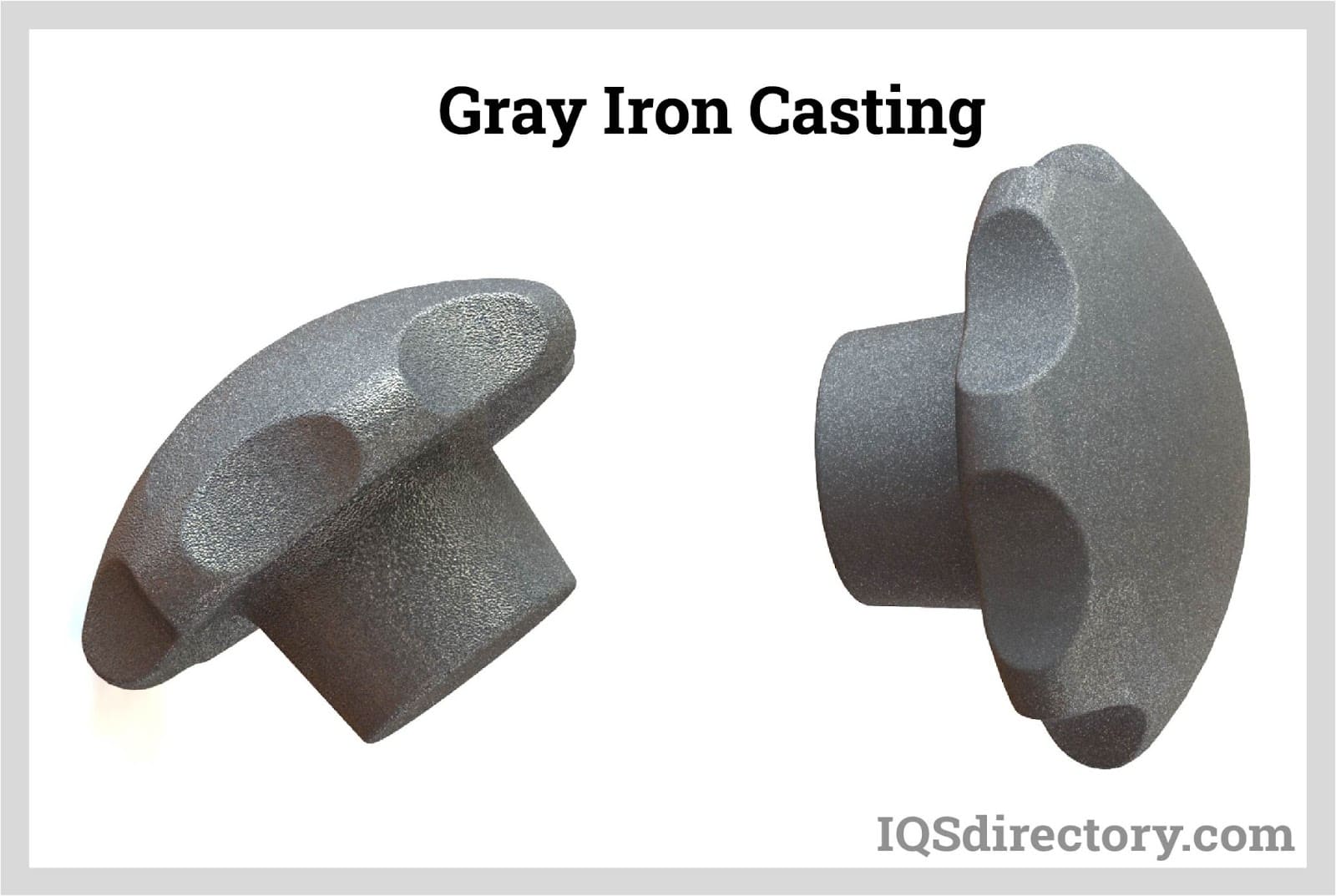

Grey Hlau Casting

Cov yam ntxwv ntawm grey cam khwb cia hlau yog cov duab microstructure, uas muaj peev xwm ua rau tawg rau cov khoom thiab muaj ib tug grey tsos. Qhov no yog hom cam khwb cia hlau uas siv ntau tshaj plaws thiab tseem siv cov khoom cam khwb cia raws li qhov hnyav. Feem ntau ntawm cov grey cam khwb cia hlau muaj cov tshuaj decomposition ntawm 2.5 feem pua rau 4 feem pua carbon, 1 feem pua rau 3 feem pua ntawm silicone thiab tus so yog cov hlau.

Hom cam khwb cia hlau no muaj zog tensile tsawg thiab tsis tshua muaj kev poob siab piv rau cov hlau. Nws lub zog compressive yog piv rau qis thiab nruab nrab carbon steel.

Tag nrho cov khoom siv tshuab no yog tswj los ntawm graphite flake cov duab thiab qhov loj ntawm graphite flakes, uas muaj nyob rau hauv microstructure ntawm grey cam khwb cia hlau.

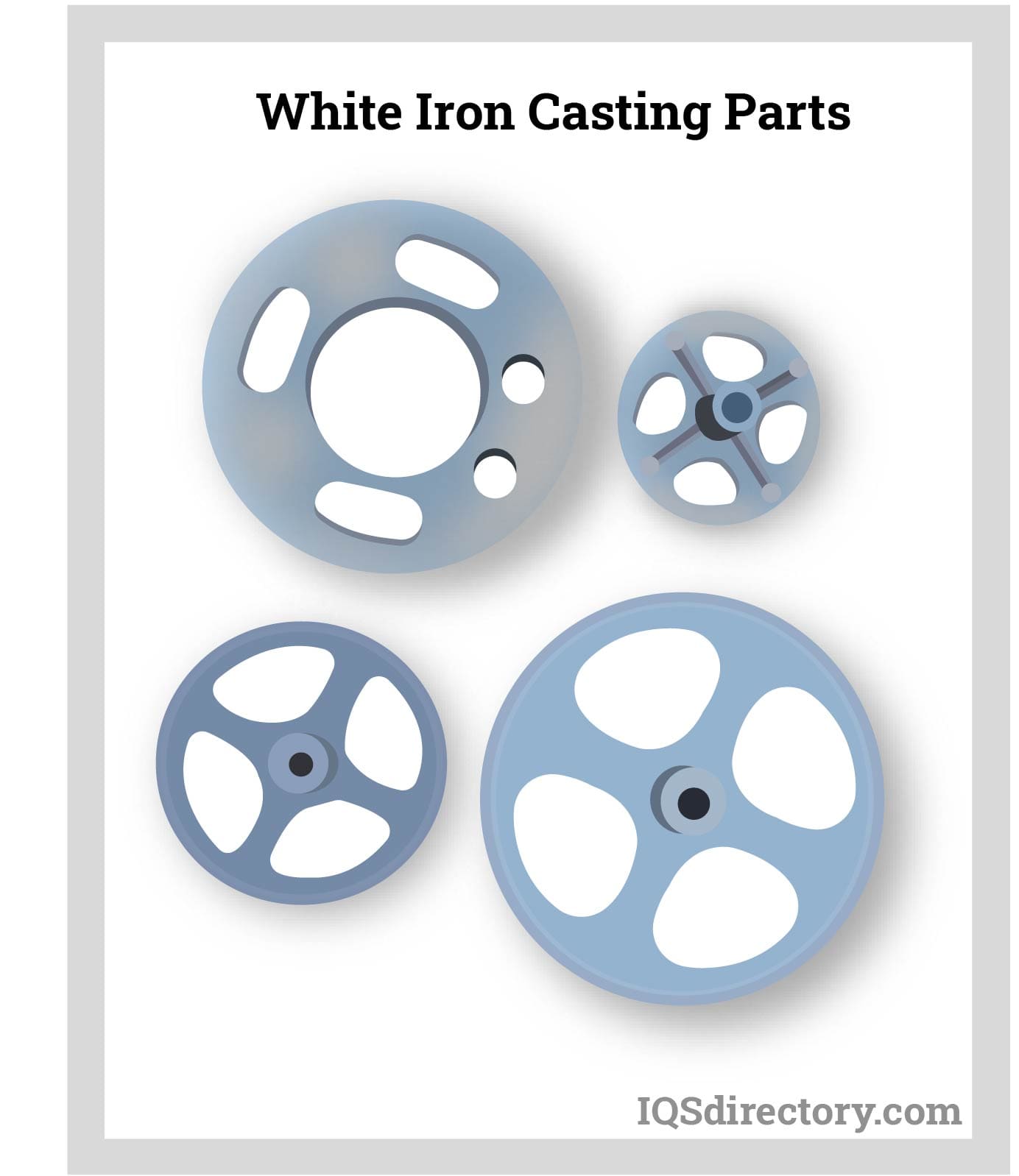

Dawb Hlau Casting

Hom hlau no muaj cov pob txha tawg uas yog dawb vim muaj cov hlau carbide precipitate hu ua cementite. Cov pa roj carbon uas muaj nyob rau hauv dawb cam khwb cia hlau precipitates tawm ntawm cov yaj raws li tau raws li theem ruaj khov cementite es tsis yog graphite. Qhov no tau ua tiav nrog cov ntsiab lus qis dua silicon raws li tus neeg sawv cev graphitizing thiab cov khoom cua txias sai dua. Tom qab cov nag lossis daus no, cov cementite tsim raws li cov khoom loj.

Thaum nag lossis daus ntawm cov hlau carbide, cov nag lossis daus rub cov pa roj carbon monoxide los ntawm qhov qub yaj, yog li txav cov sib tov mus rau ib qho uas ze rau eutectic. Cov theem ntxiv yog txo cov hlau rau carbon austenite, uas hloov mus rau martensite ib zaug txias.

Cov muaj eutectic carbides loj dhau los muab cov txiaj ntsig ntawm nag lossis daus hardening. Hauv qee cov steels tej zaum yuav muaj ntau me me cementite precipitates uas yuav nqa lub deformation ntawm yas los ntawm impeding lub zog ntawm dislocations los ntawm cov ntshiab hlau ferrite matrix. Lawv muaj qhov zoo dua thaum lawv nce qhov nyuaj ntawm cov cam khwb cia hlau vim lawv tus kheej hardness thiab ntim feem. Qhov no ua rau cov hardness ntau tuaj yeem kwv yees los ntawm txoj cai ntawm kev sib tov.

Qhov hardness no muaj nyob rau ntawm tus nqi ntawm toughness nyob rau hauv txhua rooj plaub. Dawb cam khwb cia hlau feem ntau tuaj yeem faib ua cov cement, vim carbide ua ib feem loj ntawm cov khoom. Cov hlau dawb yog nkig dhau los siv rau hauv cov khoom siv, tab sis vim nws qhov zoo hardness, tsis kam mus rau abrasion, thiab tus nqi qis, nws tuaj yeem siv los ua qhov hnav ntawm slurry twj.

Nws yog ib qho nyuaj rau txias tuab castings ntawm ib tug ceev npaum li cas uas yog txaus rau solidify lub yaj li dawb cam khwb cia hlau, txawm li cas los xij ceev txias yuav tsum tau muab los siv nyob rau hauv thiaj li yuav solidify lub ntuj raug txim ntawm dawb cam khwb cia hlau thiab tom qab no ib tug seem ntawm nws yuav tsum. txias ntawm qeeb qeeb yog li tsim ib qho tseem ceeb ntawm grey cam khwb cia hlau. Qhov tshwm sim no yog hu ua chilled casting, thiab nws muaj cov txiaj ntsig ntawm muaj qhov tawv tawv tab sis nrog lub zog sab hauv.

High chromium dawb hlau alloys muaj peev xwm tso cai loj casting txog li 10 tonne impeller los ua xuab zeb nrum. Qhov no yog vim qhov tseeb tias cov chromium txo cov cua txias uas yuav tsum tau tsim cov carbides los ntawm cov thicknesses ntau dua ntawm cov khoom. Carbides nrog kev puas tsuaj zoo heev kuj yog tsim los ntawm cov ntsiab lus chromium.

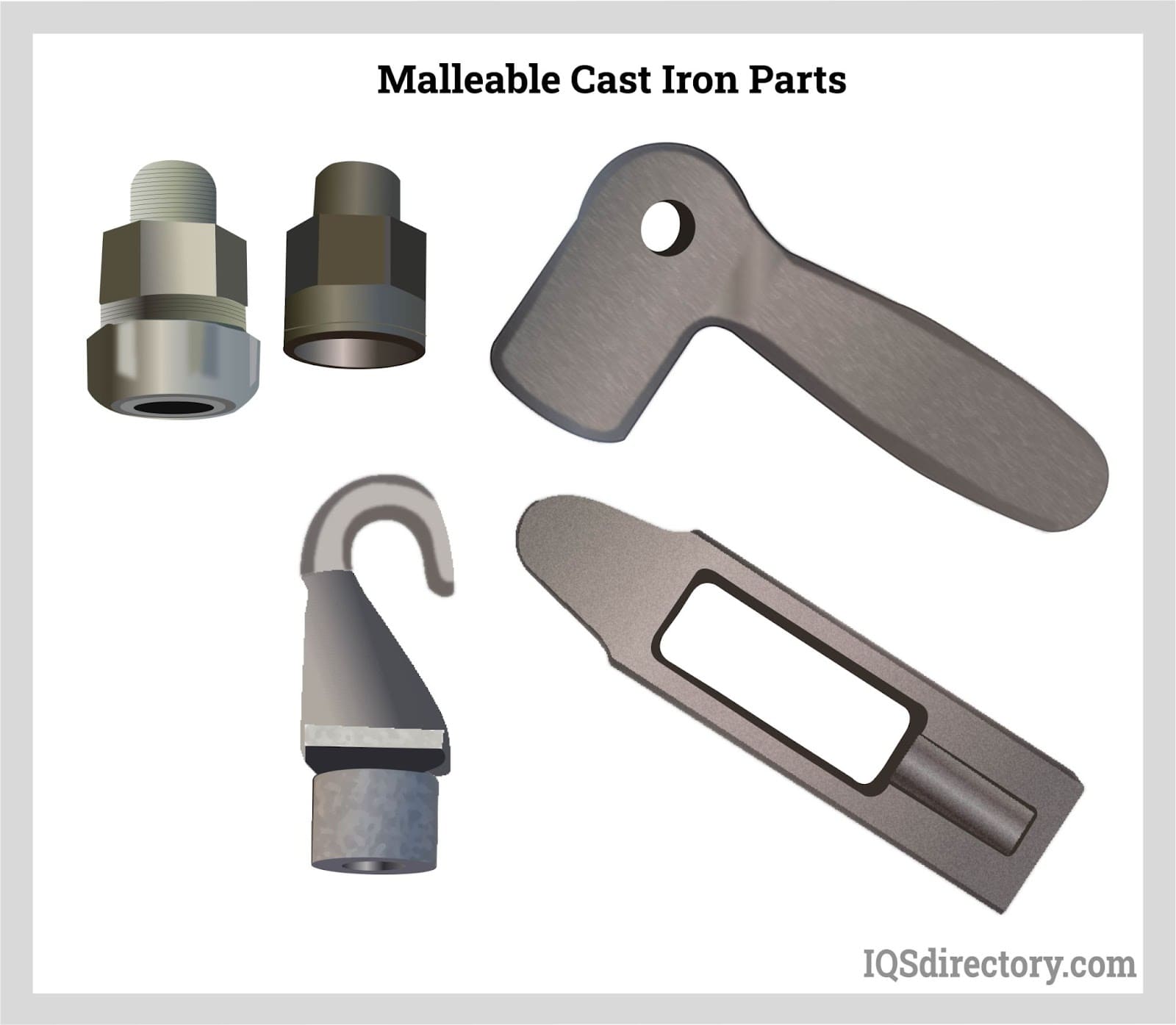

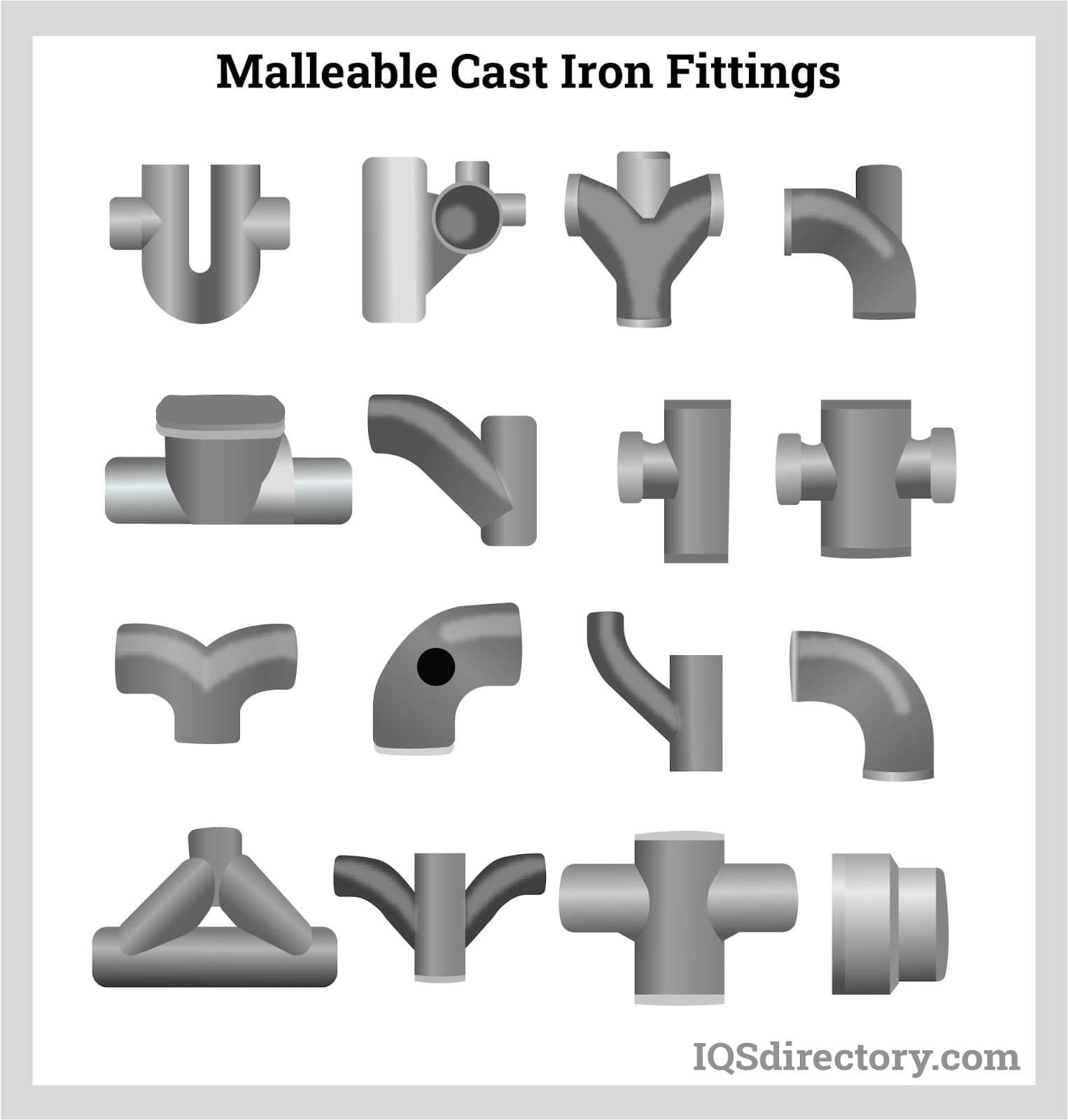

Malleable Hlau Casting

Malleable cam khwb cia hlau pib raws li ib tug dawb hlau casting, ces tshav kub kho ntawm kub txog 950 ° C rau ob los yog ib hnub, thiab ces nws yog txias rau tib lub sij hawm.

Cov pa roj carbon nyob rau hauv cov hlau carbide ces hloov mus rau hauv graphite thiab ferrite ntxiv rau cov pa roj carbon vim qhov cua sov thiab txias txheej txheem. Qhov no yog cov txheej txheem qis, tab sis nws ua rau lub ntsej muag nro los hloov cov graphite rau hauv spheroidal hais es tsis yog flakes.

Cov spheroids yog luv luv thiab sib nrug deb ntawm ib leeg vim lawv qhov qis qis. Lawv kuj muaj qhov qis qis, ua rau tawg tawg thiab photon. Raws li kev tawm tsam rau cov flakes, lawv muaj cov ciam teb tsis sib haum uas koom nrog hauv kev txo cov teeb meem kev ntxhov siab uas muaj nyob hauv grey cam khwb cia hlau. Tag nrho cov nyob rau hauv tag nrho, cov khoom muaj nyob rau hauv lub malleable cam khwb cia hlau yog ntau zoo li cov hlau uas yog me me nyob rau hauv cov xwm.

Hlau Casting

Qee lub sij hawm hu ua nodular cam khwb cia hlau, cov cam khwb cia hlau no muaj nws cov graphite hauv daim ntawv ntawm cov nodules me me, nrog cov graphite muaj cov txheej txheem uas yog concentric thiab yog li tsim cov nodules. Vim li no, cov khoom ntawmductile cam khwb cia hlauyog cov hlau spongy uas tsis muaj kev ntxhov siab cuam tshuam los ntawm cov flakes ntawm graphite.

Cov pa roj carbon concentration muaj nyob ib ncig ntawm 3 mus rau 4 feem pua, thiab cov silicon yog nyob ib ncig ntawm 1.8 feem pua rau 2.8 feem pua. Cov nyiaj me me ntawm 0.02 feem pua rau 0.1 feem pua ntawm magnesium, thiab tsuas yog 0.02 feem pua rau 0.04 feem pua cerium thaum ntxiv rau cov alloys slows tus nqi uas graphite nag lossis daus loj hlob los ntawm kev sib txuas rau graphite txoj kab npoo.

Cov pa roj carbon monoxide tuaj yeem muaj txoj hauv kev los ntawm kev sib cais raws li spheroidal hais raws li cov khoom sib zog, vim yog kev ceev faj ntawm lwm cov ntsiab lus thiab lub sijhawm kom raug thaum lub sijhawm ua haujlwm. Cov txiaj ntsig tau zoo ib yam li cov hlau cam khwb cia hlau, tab sis cov khoom tuaj yeem raug pov nrog cov seem uas loj dua.

Alloying Elements

Cov khoom ntawm cam khwb cia hlau yog hloov thiab ntxiv rau hauv ntau yam alloying ntsiab lossis alloyants hauv cov cam khwb cia hlau. Nyob rau hauv txoj kab nrog carbon yog lub caij silicon vim hais tias nws muaj peev xwm ua kom cov pa roj carbon tawm ntawm cov tshuaj. Ib feem me me ntawm silicon tuaj yeem tsis tuaj yeem ua tiav qhov no vim nws tso cai rau cov pa roj carbon nyob hauv cov tshuaj, yog li tsim cov hlau carbide thiab tseem tsim cov hlau cam khwb cia dawb.

Qhov feem pua loj dua lossis concentration ntawm silicon tuaj yeem yuam cov pa roj carbon monoxide tawm ntawm cov tshuaj thiab tom qab ntawd tsim graphite thiab tseem tsim cov hlau cam khwb cia grey. Lwm cov khoom siv alloying tsis tau sau tseg suav nrog manganese, chromium, titanium thiab tom qab ntawd vanadium. Cov tshuaj tiv thaiv silicon, lawv kuj txhawb nqa cov pa roj carbon monoxide thiab yog li tsim cov carbides. Nickel thiab lub caij tooj liab muaj qhov zoo dua vim lawv ua kom muaj zog thiab ua haujlwm, tab sis lawv tsis tuaj yeem hloov pauv cov pa roj carbon ntau.

Cov pa roj carbon uas yog nyob rau hauv daim ntawv ntawm graphite ua rau cov hlau softer, yog li txo cov nyhuv ntawm shrinkage, txo lub zog thiab txo qhov ntim. Sulfur feem ntau yog cov kab mob sib kis thaum muaj, thiab nws tsim cov hlau sulfide uas tiv thaiv kev tsim ntawm graphite thiab tseem ua rau cov tawv tawv.

Qhov tsis zoo ntawm leej faj yog tias nws ua rau molten cam khwb cia hlau khov, uas ua rau muaj qhov tsis xws luag. Txhawm rau kom noj thiab tshem tawm cov teebmeem ntawm leej faj, manganese ntxiv rau cov tshuaj. Qhov no yog ua tiav vim thaum ob qho tib si ua ke lawv tsim manganese sulfide es tsis txhob hlau sulfide. Qhov tshwm sim manganese sulfide yog sib zog dua li yaj thiab nyhav tawm ntawm cov yaj thiab nkag mus rau hauv slag.

Kwv yees li ntawm manganese xav tau los tshem tawm cov teebmeem ntawm leej faj yog 1.7 units ntawm leej faj cov ntsiab lus thiab ntxiv 0.3 feem pua rau saum. Qhov ntxiv ntawm ntau tshaj li qhov no ntawm manganese ua rau tsim cov manganese carbide thiab qhov no nce hardness thiab chilling tshwj tsis yog nyob rau hauv grey hlau qhov twg mus txog rau 1 feem pua ntawm manganese yuav ua rau kom muaj zog thiab ceev muaj. Nickel yog ib qho ntawm feem ntau alloying ntsiab vim hais tias nws muaj ib tug nyiam ntawm refining lub pearlite thiab cov qauv ntawm graphite, yog li txhim kho lub toughness, thiab evens tawm lub hardness sib txawv ntawm seem thicknesses.

Chromium yog ntxiv rau me me kom txo cov graphite dawb thiab ua kom txias. Qhov no yog vim chromium yog lub zog carbide stabilizer, thiab qee zaum nws tuaj yeem ua haujlwm nrog npib tsib xee. Rau chromium kuj, ib qho me me ntawm cov tin tuaj yeem ntxiv. Copper yog ntxiv rau hauv lub ladle lossis rauv rau ntawm qhov kev txiav txim ntawm 0.5 feem pua rau 2.5 feem pua kom ua tiav qhov txias txias, ua kom cov graphite, thiab qhov nce hauv fluidity. Molybdenum kuj tuaj yeem muab ntxiv rau hauv qhov kev txiav txim ntawm 0.3 feem pua rau 1 feem pua kom thiaj li ua kom txias, ua kom cov graphite, thiab kho cov qauv pearlite.

Nws yog feem ntau ntxiv ua hauj lwm nyob rau hauv txoj kab nrog npib tsib xee, tooj liab, thiab chromium los tsim cov hlau muaj zog. Lub caij titanium ntxiv rau kev ua haujlwm ua tus degasser thiab deoxidizer, thiab ua kom muaj dej ntau ntxiv. Qhov feem ntawm 0.15 feem pua rau 0.5 feem pua ntawm cov ntsiab lus vanadium ntxiv rau cov hlau cam khwb cia thiab pab kom ruaj khov cementite, ua kom tawv tawv thiab tiv thaiv kev hnav thiab kub.

Zirconium pab tsim graphite thiab ntxiv nyob rau hauv proportions ntawm 0.1 feem pua rau 0.3 feem pua. Cov ntsiab lus no tseem pab hauv deoxidizing thiab nce fluidity. Nyob rau hauv malleable hlau melts, kom ntau npaum li cas silicon ntxiv, bismuth yog poured nyob rau hauv ib tug scale ntawm 0.002 feem pua rau 0.01 feem pua. Hauv cov hlau dawb, lub caij boron ntxiv, uas pab tsim cov hlau uas yog malleable, thiab nws txo cov coarsening nyhuv ntawm lub caij bismuth.