Mitundu ya Iron Castings

Mitundu ya Iron Castings

Mutuwu ufotokoza mitundu yosiyanasiyana ya chitsulo.

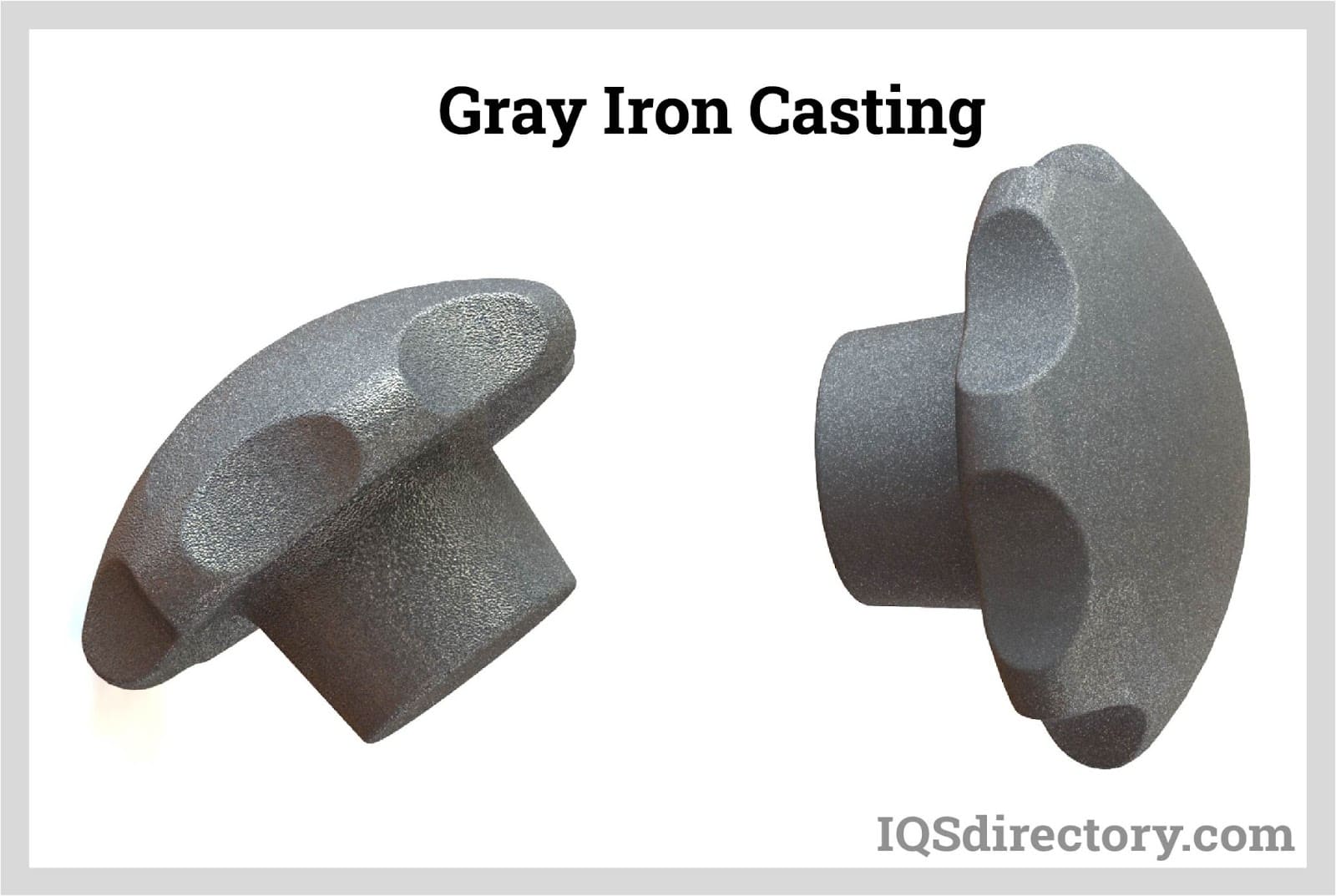

Gray Iron Casting

Maonekedwe a chitsulo chotupitsa ndi graphic microstructure, yomwe imatha kupangitsa kuti zinthu ziwonongeke komanso kukhala ndi imvi. Uwu ndi mtundu womwe umagwiritsidwa ntchito kwambiri pazitsulo zotayidwa komanso zomwe zimagwiritsidwa ntchito kwambiri potengera kulemera kwake. Zitsulo zambiri za imvi zimakhala ndi kuwonongeka kwa mankhwala kwa 2.5 peresenti mpaka 4 peresenti ya carbon, 1 peresenti mpaka 3 peresenti ya silikoni ndipo zina zonse ndizopangidwa ndi chitsulo.

Chitsulo chamtundu woterechi chimakhala ndi mphamvu zocheperapo komanso kukana kugwedezeka poyerekeza ndi chitsulo. Mphamvu yake yopondereza ikufanana ndi chitsulo chotsika komanso chapakati cha carbon.

Zinthu zonsezi zimayendetsedwa ndi mawonekedwe a graphite flake ndi kukula kwa ma graphite flakes, omwe amapezeka mu microstructure ya chitsulo cha imvi.

White Iron Casting

Chitsulo chamtunduwu chimakhala ndi malo osweka omwe amakhala oyera chifukwa cha kukhalapo kwa chitsulo cha carbide precipitate chotchedwa cementite. Mpweya womwe uli mu chitsulo choyera umatuluka mu chitsulo chosungunuka ngati chitsulo chokhazikika cha simenti osati ngati graphite. Izi zimatheka ndi zinthu zochepa za silicon monga graphitizing wothandizira komanso kuzizira komwe kumaperekedwa mwachangu. Pambuyo pa mvula iyi, simenti imapanga ngati tinthu tating'onoting'ono.

Panthawi ya mvula ya carbide yachitsulo, mpweyawo umatulutsa carbon kuchokera kusungunuka koyambirira, motero kusuntha kusakaniza kumodzi komwe kuli pafupi ndi eutectic. Gawo lotsala ndikutsitsa chitsulo kukhala carbon austenite, chomwe chimasandulika kukhala martensite chikakhazikika.

Izi zili ndi eutectic carbides ndizazikulu kwambiri kuti zisapereke phindu la kuuma kwa mvula. M'zitsulo zina pakhoza kukhala timitsinje tating'ono ta simenti timene titha kunyamula mapindikidwe a pulasitiki polepheretsa kusuntha kwazomwe zimasunthika kudzera muzitsulo zoyera za ferrite. Iwo ali ndi mwayi pamene akuwonjezera kuuma kochuluka kwa chitsulo chosungunuka chifukwa cha kuuma kwawo ndi gawo la voliyumu. Izi zimabweretsa kuuma kochuluka kutha kuyerekezedwa ndi lamulo la zosakaniza.

Kuuma uku kumaperekedwa chifukwa cha kuuma mulimonse. Chitsulo choyera chimatha kutchulidwa ngati simenti, chifukwa carbide imapanga gawo lalikulu lazinthuzo. Chitsulo choyera ndi chosasunthika kwambiri kuti chigwiritsidwe ntchito pamapangidwe ake, koma chifukwa cha kuuma kwake, kusagwirizana ndi abrasion, ndi mtengo wotsika, chitha kugwiritsidwa ntchito ngati kuvala pamwamba pa mapampu a slurry.

Ndikovuta kuziziritsa zitsulo zokhuthala mwachangu zomwe zimakwanira kusungunuka ngati chitsulo choyera, komabe kuziziritsa mwachangu kungagwiritsidwe ntchito kuti kulimbitsa gehena yachitsulo choyera ndipo pambuyo pake chotsaliracho chidzakhala. kuziziritsa pang'onopang'ono motero kupanga pakati pa chitsulo chotuwa. Kujambula kumeneku kumatchedwa chilled casting, ndipo kumakhala ndi ubwino wokhala ndi malo olimba koma mkati mwake molimba.

Ma aloyi achitsulo a chromium oyera anali ndi kuthekera kolola kuponya kwakukulu kwa pafupifupi matani 10 kukhala mchenga. Izi ndichifukwa choti chromium imachepetsa kuziziritsa komwe kumafunikira kuti apange ma carbides kudzera mu makulidwe akulu azinthu. Ma Carbides okhala ndi kukana bwino kwa abrasion amapangidwanso ndi zinthu za chromium.

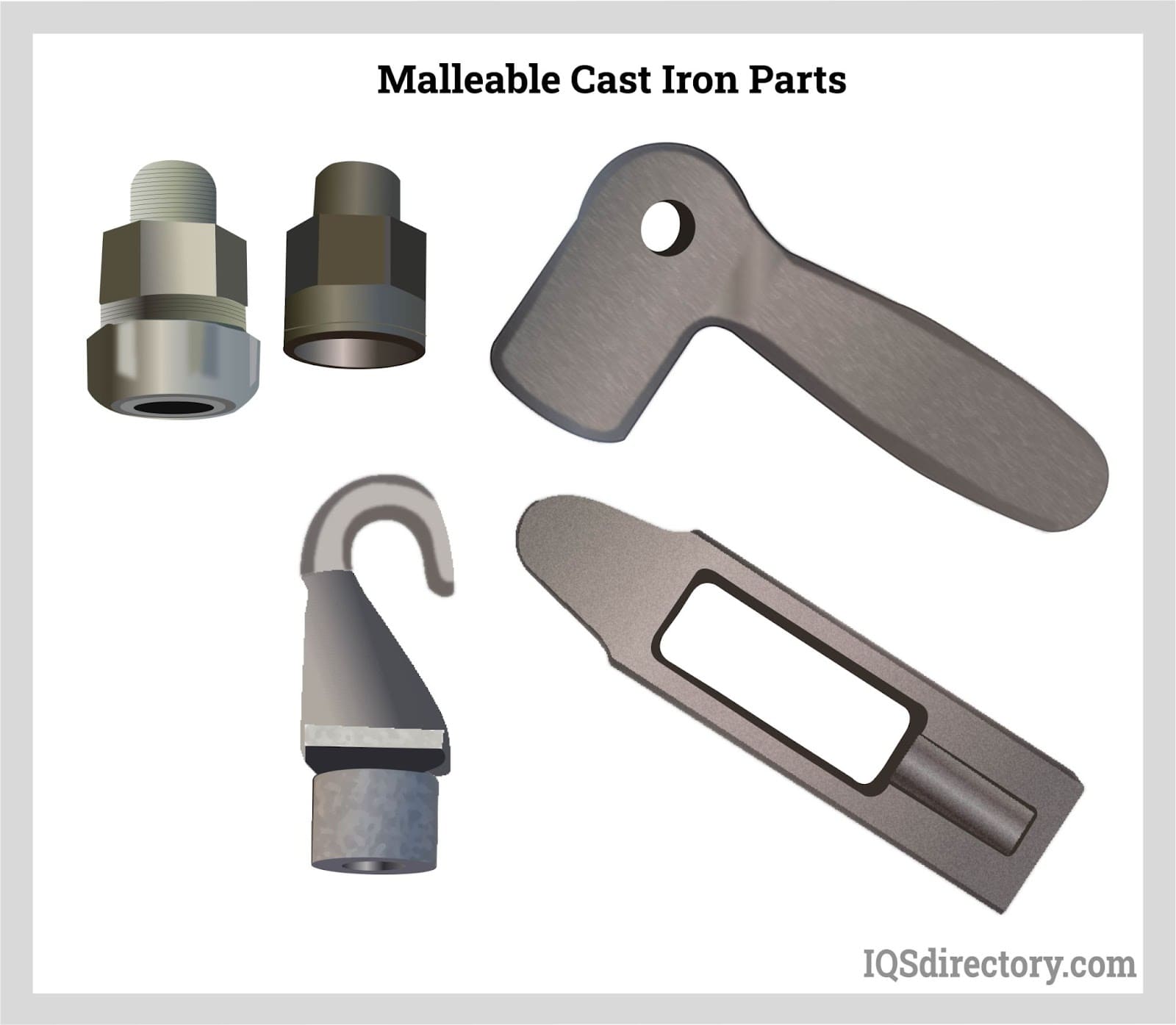

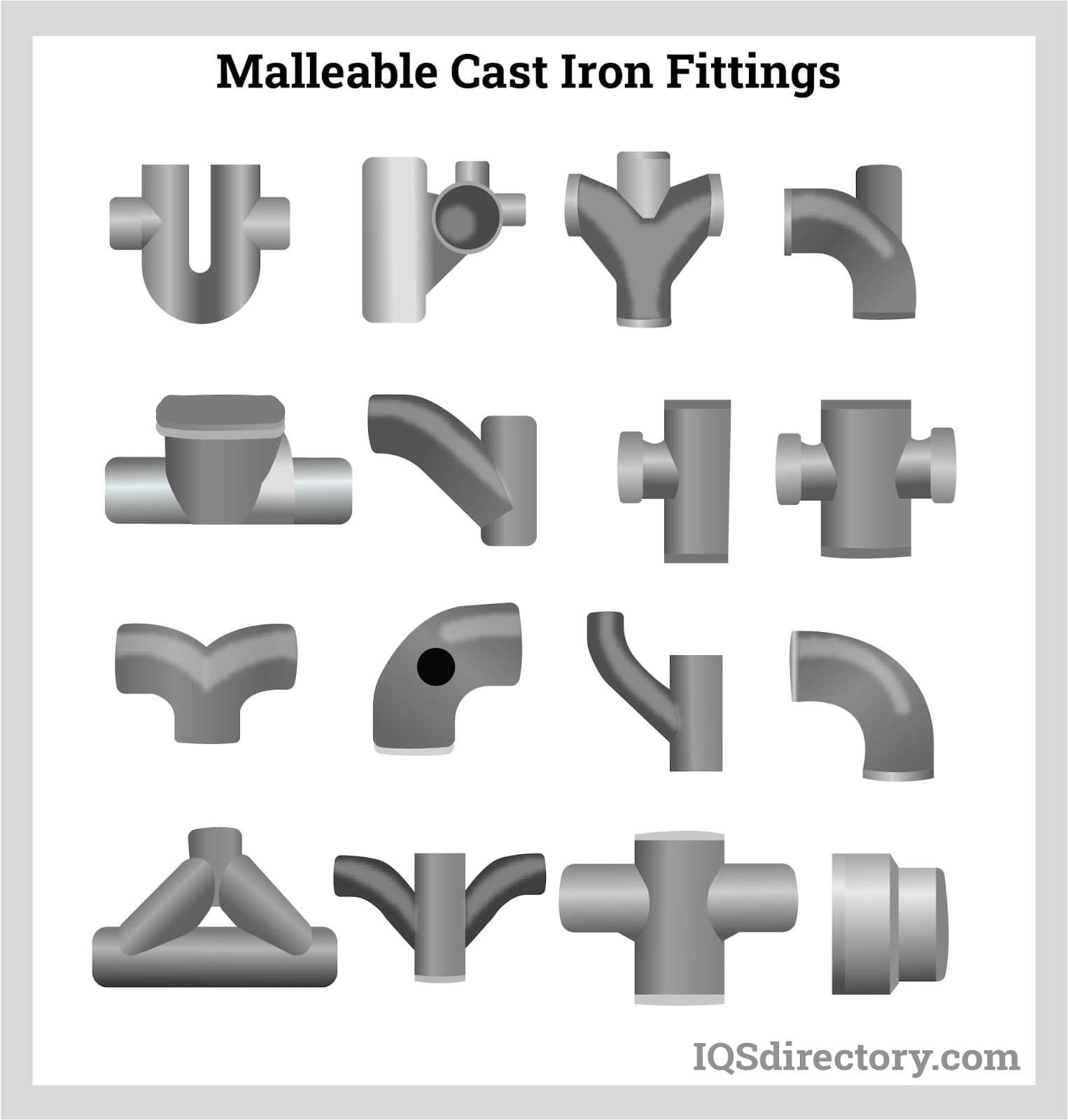

Malleable Iron Casting

Chitsulo chosungunuka chimayamba ngati kuponyedwa kwachitsulo choyera, kenako kutentha kumatenthedwa pafupifupi 950 ° C kwa masiku awiri kapena tsiku limodzi, kenako kumakhazikika kwa nthawi yomweyo.

Mpweya wa carbon mu iron carbide umasandulika kukhala graphite ndi ferrite kuphatikiza carbon chifukwa cha kutentha ndi kuzizira kumeneku. Iyi ndi njira yotsika, koma imapangitsa kuti kugwedezeka kwa pamwamba kusinthe graphite kukhala particles spheroidal osati flakes.

Ma spheroids ndi aafupi komanso atalikirana chifukwa cha chiŵerengero chawo chochepa. Amakhalanso ndi gawo lotsika, lofalitsa ming'alu ndi photon. Mosiyana ndi ma flakes, ali ndi malire osamveka omwe amathandizira kuchepetsa kupsinjika kwamavuto omwe amapezeka muiron imvi. Zonsezi, zinthu zomwe zimaphatikizidwa muchitsulo chosungunula chosungunuka zimakhala ngati zitsulo zomwe zimakhala zofatsa.

Kuponya kwa Iron Ductile

Nthawi zina amatchedwa nodular cast iron, chitsulo chonyezimira ichi chimakhala ndi graphite yake m'mawonekedwe a tinthu tating'onoting'ono kwambiri, pomwe graphite imakhala ndi mawonekedwe a zigawo zomwe zimakhala zokhazikika ndipo motero zimapanga timinofu. Chifukwa cha ichi, katundu waductile cast ironndi a zitsulo spongy amene alibe mavuto ndende zotsatira opangidwa ndi flakes wa graphite.

Kuchuluka kwa carbon komwe kuli ndi pafupifupi 3 peresenti mpaka 4 peresenti, ndipo ya silicon ili pafupi 1.8 peresenti mpaka 2.8 peresenti. Zochepa za 0.02 peresenti kufika pa 0.1 peresenti ya magnesiamu, ndipo 0.02 peresenti mpaka 0.04 peresenti ya cerium ikawonjezeredwa kuzitsulozi zimachepetsa mlingo umene mpweya wa graphite umakulirakulira kupyolera m'mphepete mwa njira za graphite.

Mpweya ukhoza kukhala ndi mwayi wolekanitsa ngati tinthu tating'onoting'ono momwe zinthu zimalimba, chifukwa choyang'anira mosamala zinthu zina komanso nthawi yoyenera panthawiyi. Zotsatira zake zimakhala zofanana ndi chitsulo chosungunuka, koma mbali zake zimatha kuponyedwa ndi zigawo zazikulu.

Alloying Elements

The katundu wa chitsulo chotayidwa amasinthidwa ndi kuwonjezeredwa zinthu zosiyanasiyana alloying kapena ma alloyants mu chitsulo chotayidwa. Mogwirizana ndi kaboni ndi chinthu cha silicon chifukwa chimatha kukakamiza kaboni kuchoka mu yankho. Gawo laling'ono la silicon silingathe kukwaniritsa izi chifukwa limalola mpweya kukhalabe mu yankho, motero kupanga carbide yachitsulo komanso kupanga chitsulo choyera.

Kuchuluka kapena kuchuluka kwa silicon kumatha kukakamiza mpweya kuti utuluke mu yankho kenako kupanga graphite ndikupanga chitsulo chotuwa. Ma alloying ena omwe sanatchulidwe ndi manganese, chromium, titaniyamu kenako vanadium. Izi zimatsutsana ndi silicon, zimalimbikitsanso kusungidwa kwa carbon komanso kupanga mapangidwe a carbides. Nickel ndi element mkuwa ali ndi mwayi pamene amawonjezera mphamvu ndi machinability, koma samatha kusintha kuchuluka kwa mpweya wopangidwa.

Mpweya womwe uli mu mawonekedwe a graphite umapangitsa chitsulo chofewa, motero kuchepetsa zotsatira za kuchepa, kuchepetsa mphamvu ndi kuchepetsa kuchulukana komwe kulipo. Sulfure nthawi zambiri imakhala yonyansa ikasungidwa, ndipo imapanga iron sulfide yomwe imalepheretsa kupanga graphite komanso yomwe imawonjezera kuuma.

Choyipa chomwe chimapangidwa ndi sulfure ndikuti chimapangitsa chitsulo chosungunuka kukhala viscous, chomwe chimayambitsa zolakwika. Kuti athetse ndi kuthetsa zotsatira za sulfure, manganese amawonjezeredwa ku yankho. Izi zimachitika chifukwa chakuti ziwirizi zikaphatikizidwa zimapanga manganese sulfide m’malo mwa iron sulfide. Zotsatira za manganese sulfide ndi zopepuka kuposa kusungunuka ndipo zimakonda kuyandama kuchokera kusungunuka ndi kulowa mu slag.

Pafupifupi kuchuluka kwa manganese ofunikira kuti athetse zotsatira za sulfure ndi mayunitsi 1.7 a sulfure ndi 0.3 peresenti yowonjezera pamwamba. Kuonjezera kuchuluka kwa manganese kumeneku kumapangitsa kupanga manganese carbide ndipo izi zimawonjezera kuuma ndi kuzizira kupatula muiron imvi pomwe mpaka 1 peresenti ya manganese imatha kuwonjezera mphamvu ndi kachulukidwe komwe kali. Nickel ndi imodzi mwazinthu zomwe zimagwiritsidwa ntchito kwambiri chifukwa zimakhala ndi chizolowezi choyenga pearlite ndi mapangidwe a graphite, motero amawongolera kulimba, komanso amasiyanitsa kuuma pakati pa makulidwe a gawo.

Chromium imawonjezedwa pang'ono kuti muchepetse graphite yaulere ndikupanga kuzizira. Izi zili choncho chifukwa chromium ndi mphamvu ya carbide stabilizer, ndipo nthawi zina imatha kugwira ntchito limodzi ndi faifi tambala. Kwa chromiumnso, tini tating'ono tating'ono titha kuwonjezedwa. Mkuwa amawonjezeredwa mu ladle kapena ng'anjo pa dongosolo la 0.5 peresenti mpaka 2.5 peresenti kuti akwaniritse kuzizira, kuyeretsa graphite, ndi kuwonjezereka kwa madzi. Molybdenum imathanso kuwonjezeredwa mwadongosolo la 0.3 peresenti mpaka 1 peresenti kuti muwonjezerenso kuzizira, kuyeretsa graphite, ndikuyeretsa kapangidwe ka pearlite.

Nthawi zambiri amawonjezeredwa pogwira ntchito mogwirizana ndi faifi tambala, mkuwa, ndi chromium kuti apange zitsulo zolimba kwambiri. Titaniyamu imawonjezeredwa kuti igwire ntchito ngati degasser ndi deoxidizer, ndikuwonjezera madzimadzi. Magawo a 0.15 peresenti mpaka 0.5 peresenti ya chinthu cha vanadium amawonjezeredwa kuchitsulo chachitsulo ndikuthandizira kukhazikika kwa simenti, kuonjezera kuuma komanso kukana kuvala ndi kutentha.

Zirconium imathandiza kupanga graphite ndipo imawonjezeredwa pafupifupi 0.1 peresenti mpaka 0.3 peresenti. Chigawochi chimathandizanso pa deoxidizing ndi kuonjezera fluidity. Mu chitsulo chosungunula, kuti muwonjezere kuchuluka kwa silicon yomwe ingawonjezedwe, bismuth imatsanuliridwa mu sikelo ya 0,002 peresenti mpaka 0.01 peresenti. Mu chitsulo choyera, chinthu cha boron chimawonjezeredwa, chomwe chimathandizira kupanga chitsulo chomwe chimasungunuka, ndipo chimachepetsa kuyabwa kwa bismuth.