Mhando dzeIron Castings

Mhando dzeIron Castings

Chitsauko chino chichakurukura marudzi akasiyana-siyana ekuumbwa kwesimbi.

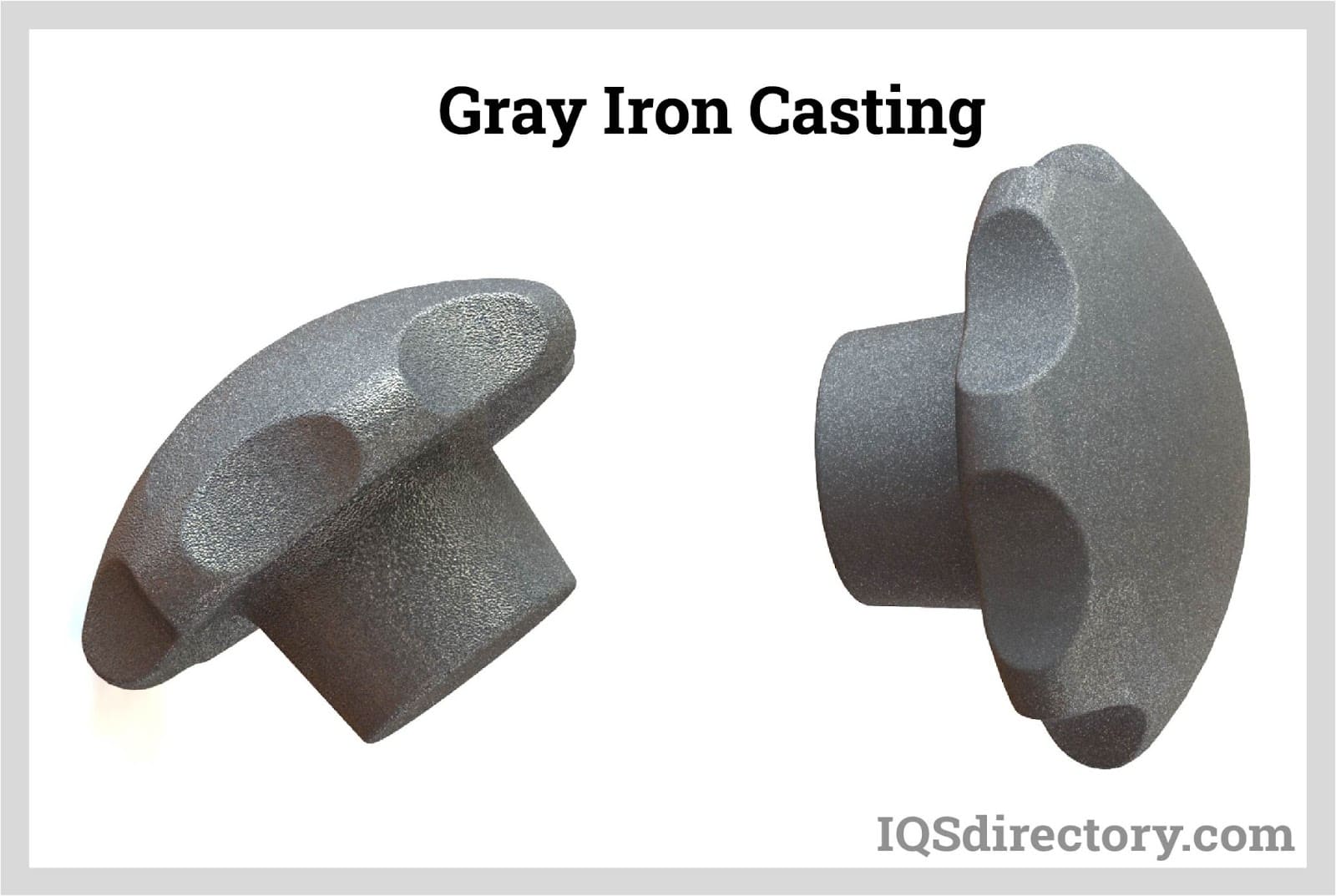

Grey Iron Casting

Hunhu hwegrey cast iron ndeye graphic microstructure, iyo inokwanisa kukonzera kuputsika kune izvo zvinhu uye kuita grey kutaridzika. Iyi ndiyo inonyanya kushandiswa mhando yesimbi yakakandwa uye zvakare inowanzoshandiswa yakakandwa zvinhu zvinoenderana nehuremu. Ruzhinji rwe grey cast irons ine kemikari yakaora inosvika 2.5 muzana kusvika 4 muzana kabhoni, 1 muzana kusvika 3 muzana silicone uye imwe yasara inoumbwa nesimbi.

Iri rudzi rwesimbi yakakandwa ine simba shoma uye kushomeka kwekudzivirira kuvhunduka kana ichienzaniswa nesimbi. Simba rayo rekumanikidza rinofananidzwa nesimbi yakaderera uye yepakati kabhoni.

Zvese izvi zvemakanika zvivakwa zvinodzorwa nechimiro chegraphite flake uye saizi yemagraphite flakes, aripo mune microstructure yegrey cast iron.

White Iron Casting

Iyi mhando yesimbi ine nzvimbo dzakatsemuka dzakachena nekuda kwekuvapo kwesimbi carbide precipitate inonzi cementite. Iyo kabhoni iri muwhite cast iron inodonha kubva mukunyunguduka sezvakasangana yakagadzikana chikamu simende kwete se graphite. Izvi zvinowanikwa neyakadzikira silicon yemukati seiyo graphitizing agent uye nekukurumidza kupihwa kutonhora chiyero. Mushure mekunaya uku, simende inoumba sezvimedu zvakakura.

Munguva yekunaya kwesimbi carbide, iyo precipitate inokwevera kabhoni kubva kunyungudika kwepakutanga, nokudaro ichifambisa musanganiswa kune imwe iri padyo ne eutectic. Chikamu chasara ndechekudzikisa iron kune kabhoni austenite, iyo inoshandura kuita martensite kana yatonhodzwa.

Aya ane eutectic carbides akakurisa kuti ape mukana wekuoma kwemvura. Mune mamwe masimbi panogona kunge paine madiki simenti emvura anogona kutakura deformation yepurasitiki nekukanganisa kufamba kwekutsemuka kuburikidza nesimbi yakachena ferrite matrix. Vane mukana sezvavanowedzera kuomarara kwesimbi yakakandwa nekuda kwekuoma kwavo uye chikamu chevhoriyamu. Izvi zvinoita kuti kuomarara kwakawanda kukwanise kuenzaniswa nemutemo wemisanganiswa.

Uku kuoma kunopihwa pamutengo wekuomarara mune chero mamiriro ezvinhu. White cast iron inogona kurongedzerwa semendi, sezvo carbide ichiita chikamu chakakura chechinhu. Simbi chena yakanyanyisa brittle kuti ishandiswe muzvikamu zvezvimiro, asi nekuda kwekunaka kwayo kuoma, kuramba kune abrasion, uye kudhura kwakaderera, inogona kushandiswa seyakapfekwa pamusoro pemapombi ane slurry.

Zvakaoma kutonhodza makanda akakora nekukurumidza izvo zvinokwana kuomesa kunyunguduka sesimbi chena, zvisinei kutonhora nekukurumidza kunogona kushandiswa kuomesa gehena resimbi chena uye mushure meizvi zvinosara zvichave. inotonhorera nekumhanya zvishoma nekudaro ichigadzira pakati pegrey cast iron. Kukandwa uku kunobva kwadaidzwa kuti chilled casting, uye ine mabhenefiti ekuva nenzvimbo yakaoma asi ine mukati yakaoma.

High chromium white iron alloys aive nekwaniso yekubvumira kukanda kukuru kweanosvika gumi tonne impeller kuve jecha. Izvi zvinokonzerwa nekuti iyo chromium inoderedza mwero wekutonhora unodiwa kugadzira carbides kuburikidza nehukuru hwezvinhu. Carbides ine yakanakisa abrasion kuramba inogadzirwawo nechromium zvinhu.

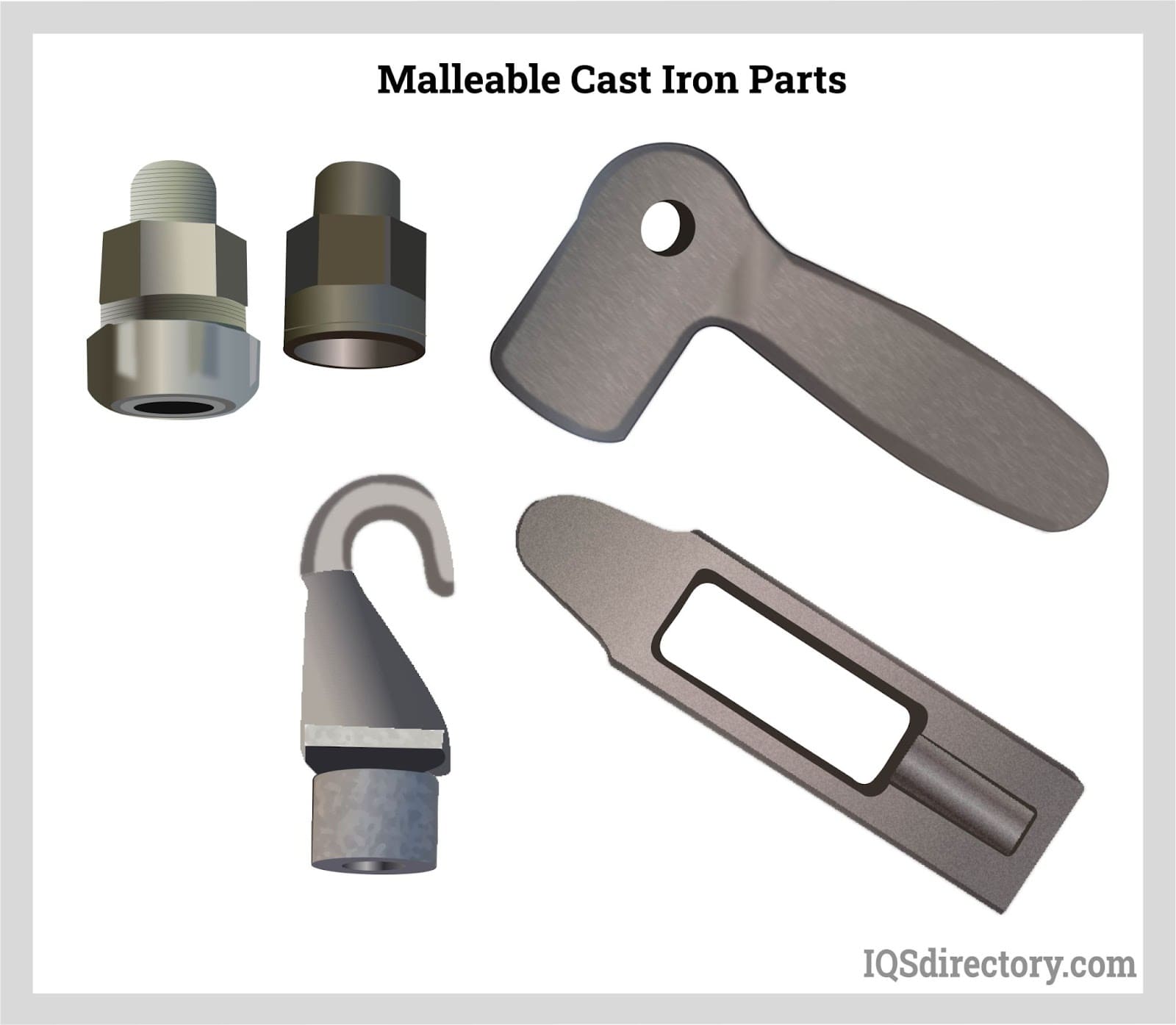

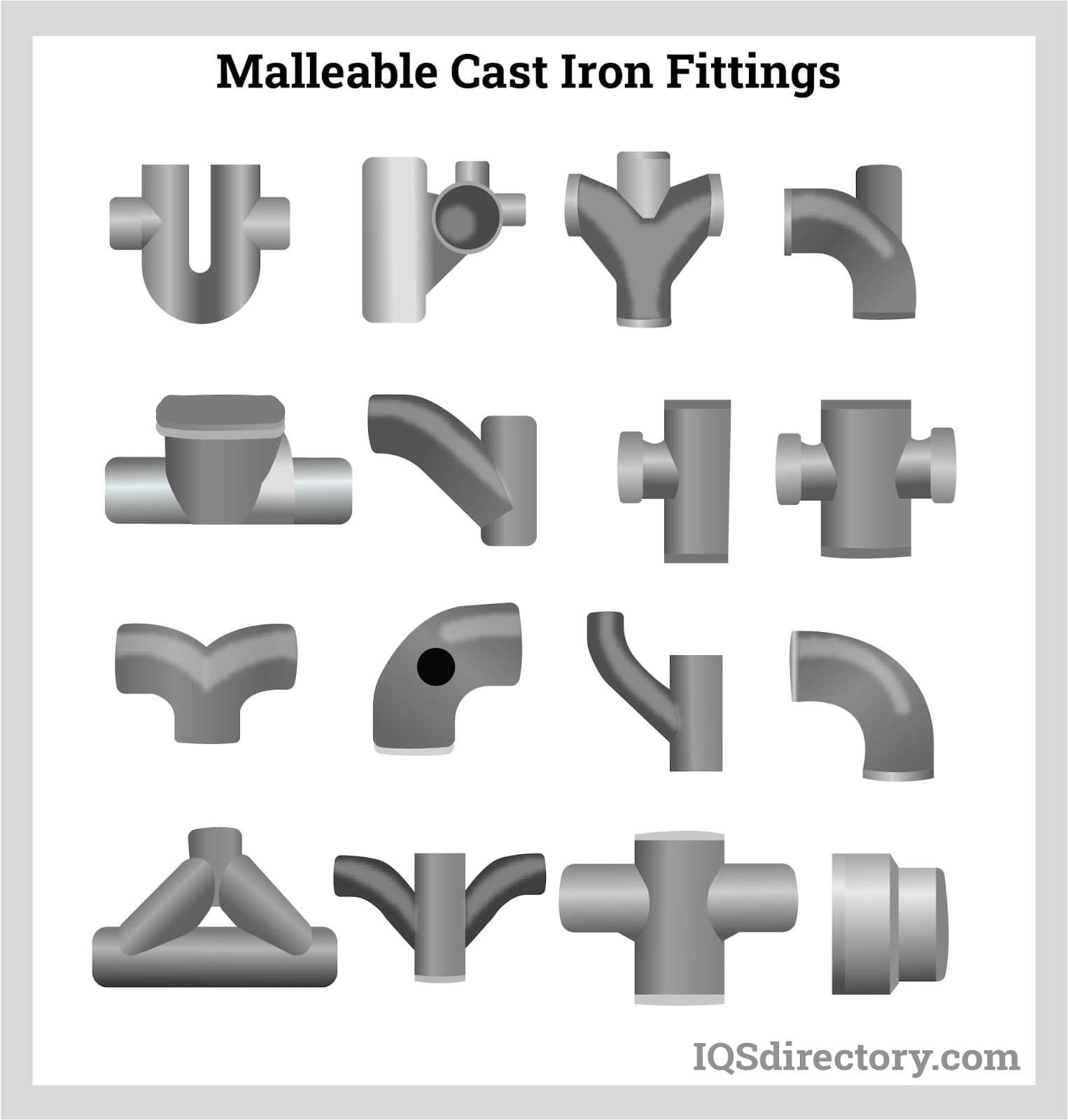

Malleable Iron Casting

Simbi inokwenenzverwa inotanga senge chena simbi inokandwa, yozopisa inobatwa patembiricha ingangoita 950°C kwemazuva maviri kana rimwe chete, yozotonhodzwa kwenguva imwe cheteyo.

Iyo kabhoni musimbi carbide inobva yachinja kuita graphite uye ferrite pamwe nekabhoni nekuda kwekudziya uye kutonhora maitiro. Iyi inzira yakaderera, asi inogonesa tension yepasi kushandura graphite kuita spheroidal particles pane maflakes.

Iwo ma spheroids ari mapfupi uye ari kure kure kubva kune mumwe nemumwe nekuda kweiyo yakaderera chikamu ratio. Iwo ane zvakare yakaderera-chikamu-chikamu, kuparadzira crack uye photon. Kusiyana nemaflakes, ane miganhu isina kujeka iyo inotora chikamu mukuderedza kushushikana kwematambudziko anowanikwa mugrey cast iron. Zvese mune zvese, zvivakwa zvinosanganisirwa musimbi inogadzika zvakada kufanana neaya esimbi ane hunyoro muhunhu.

Ductile Iron Casting

Dzimwe nguva inonzi nodular cast iron, iyi iron iron ine graphite yayo muchimiro chematinji madiki, graphite iine chimiro chemitsetse iyo iri concentric nekudaro inogadzira machunduru. Nekuda kweizvi, zvinhu zveductile cast ironndeaya esimbi ine spongy iyo isina kushushikana yekusimbisa mhedzisiro inogadzirwa nemaflakes egraphite.

Iyo kabhoni yekumisikidzwa mari irimo yakatenderedza 3 muzana kusvika 4 muzana, uye iyo yesilicon yakatenderedza 1.8 muzana kusvika 2.8 muzana. Zvishoma zvishoma zve 0.02 muzana kusvika 0.1 muzana ye magnesium, uye chete 0.02 muzana kusvika 0.04 muzana cerium kana yawedzerwa kune aya alloys inoderedza mwero wekunaya kwe graphite inokura kuburikidza nekubatana kune graphite lanes kumucheto.

Carbon inogona kuve nemukana wekuparadzanisa se spheroidal particles sezvo zvinhu zvinoomesa, nekuda kwekuchenjerera kutonga kwezvimwe zvinhu uye nguva yakakodzera panguva yekuita. Zvimedu zvinobuda zvakafanana nesimbi inogadzika, asi zvikamu zvinogona kukandwa nezvikamu zvakakura.

Alloying Elements

Izvo zvimiro zvesimbi yakakandwa zvinoshandurwa uye zvinowedzerwa mune akasiyana alloying zvinhu kana alloyants musimbi yakakandwa. Inoenderana nekabhoni ndiyo element silicon nekuti ine kugona kumanikidza kabhoni kubuda mumhinduro. Chikamu chidiki chesilicon hachikwanise kuita izvi zvizere sezvo chichibvumira kabhoni kuti irambe iri mumhinduro, nokudaro ichigadzira iron carbide uye zvakare kugadzira chena yakakanda simbi.

Iyo yakakura muzana kana kuunganidzwa kwesilicon inokwanisa kumanikidza kabhoni kubva mumhinduro uye yobva yagadzira graphite uye zvakare kugadzira grey cast iron. Mamwe maalloying agents asina kucherechedzwa anosanganisira manganese, chromium, titanium uyezve vanadium. Izvi zvinopesana nesilicon, zvinokurudzirawo kuchengetwa kwekabhoni uye nekudaro zvakare kuumbwa kwecarbides. Nickel uye element mhangura zvine mukana sezvo vachiwedzera simba uye machinability, asi ivo havazokwanisa kushandura huwandu hwekabhoni yakaumbwa.

Iyo kabhoni iyo iri muchimiro chegirafu inoguma mune simbi yakapfava, nokudaro inoderedza mhedzisiro ye shrinkage, kudzikisa simba uye kuderedza iyo irimo density. Sulfur inonyanya kusvibisa kana irimo, uye inoumba iron sulfide inodzivirira kuumbwa kwegraphite uye zvakare inowedzera kuoma.

Izvo zvakashata zvinoiswa nesarufa ndezvekuti inogadzira yakanyungudutswa simbi yakanyungudutswa viscous, iyo inokonzera kukanganisa. Kutarisira uye kubvisa migumisiro yesarufa, manganese inowedzerwa kune mhinduro. Izvi zvinoitwa nekuti kana zviviri izvi zvabatanidzwa zvinogadzira manganese sulfide pachinzvimbo che iron sulfide. Inokonzeresa manganese sulfide yakareruka kupfuura kunyunguduka uye inoyangarara kubva mukunyunguduka uye kupinda muslag.

Huwandu hunofungidzirwa hwemanganese hunodiwa kudzima mhedzisiro yesarufa zvikamu 1.7 zvesarufa zvirimo uye imwezve 0.3 muzana yakawedzerwa pamusoro. Kuwedzerwa kweinopfuura huwandu uhu hwemanganese kunokonzeresa kuumbwa kwe manganese carbide uye izvi zvinowedzera kuoma uye kutonhora kunze kwegrey iron apo inosvika 1 muzana yemanganese inogona kuwedzera simba uye density irimo. Nickel ndeimwe yeakawanda alloying element nekuti ine tsika yekunatsa pearlite uye chimiro chegraphite, nekudaro kuvandudza kuomarara, uye kuenzanisa kuomarara mutsauko pakati pechikamu chakakora.

Chromium inowedzerwa mune zvidiki kuderedza mahara graphite uye kuburitsa kutonhora. Izvi zvinodaro nekuti chromium ine simba carbide stabilizer, uye mune dzimwe nguva inogona kushanda pamwe nickel. Kune chromium zvakare, chidimbu chidiki chinotsiva cherata chinogona kuwedzerwa. Mhangura inowedzerwa muladle kana muchoto pakurongeka kwe0.5 muzana kusvika 2.5 muzana kuti iwane kutonhora kuderera, kunatsa graphite, uye kuwedzera kwemvura. Molybdenum inogonawo kuwedzerwa muhurongwa hwe0.3 muzana kusvika 1 muzana kuitira kuti uwedzerewo kutonhora, kunatsa graphite, uye kunatsa pearlite chimiro.

Inowanzowedzerwa kushanda inoenderana nickel, mhangura, uye chromium kugadzira simbi dzakasimba. Iyo element titanium inowedzerwa kushanda se degasser uye deoxidizer, uye kuwedzera fluidity. Zvikamu zve 0.15 muzana kusvika 0.5 muzana yechinhu vanadium inowedzerwa kune yakakandwa simbi uye kubatsira mukudzikamisa simende, kuwedzera kuoma uye kuramba kupfeka uye kupisa mhedzisiro.

Zirconium inobatsira kuumba graphite uye inowedzerwa muzvikamu zve 0.1 muzana kusvika 0.3 muzana. Ichi chinhu chinobatsirawo mu deoxidizing uye kuwedzera fluidity. Musimbi inonyungudika, kuti iwedzere kuwanda kwesilicon inogona kuwedzerwa, bismuth inodururwa muchiyero che 0.002 muzana kusvika 0.01 muzana. Musimbi chena, iyo element boron inowedzerwa, iyo inobatsira mukugadzirwa kwesimbi inogoneka, uye inoderedza kuomarara kwechinhu bismuth.