Mokhoa oa ho Lahlela Mould Shell

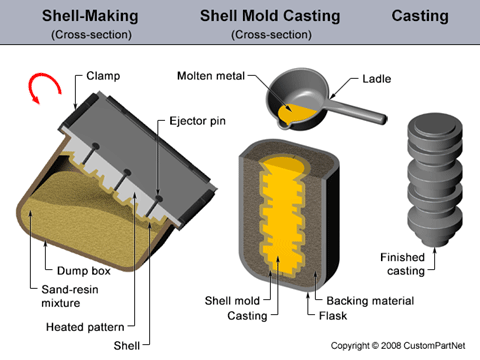

Shell mold casting ke ts'ebetso ea ho lahla tšepe e ts'oanang le ho lahla lehlabathe, ka hore tšepe e qhibilihisitsoeng e tšeloa ka har'a hlobo e ka sebelisoang. Leha ho le joalo, ha ho etsoa hlobo ea likhetla, hlobo ke khetla e nang le mabota a masesaane e entsoeng ka ho sebelisa motsoako oa lehlabathe la lehlabathe ho potoloha paterone. Sebopeho, sekotoana sa tšepe se sebopehong sa karolo e lakatsehang, se sebelisoa hape ho etsa mefuta e mengata ea likhetla. Paterone e ka sebelisoang hape e lumella litefiso tse phahameng tsa tlhahiso, athe hlobo e ka lahloang e etsa hore li-geometri tse rarahaneng li ka etsoa. Ho lahla hlobo ea khetla ho hloka tšebeliso ea paterone ea tšepe, onto, motsoako oa lehlabathe-resin, lebokose la ho lahla, le tšepe e qhibilihisitsoeng.

Ho hlahisa hlobo ea khetla ho lumella tšebeliso ea litšepe tse nang le ferrous le tse se nang ferrous, tseo hangata li sebelisang tšepe e entsoeng ka tšepe, tšepe ea carbon, alloy steel, tšepe e sa hloekang, li-alloys tsa aluminium le lisebelisoa tsa koporo. Likarolo tse tloaelehileng li na le boholo bo nyane ho isa bohareng 'me li hloka ho nepahala ho phahameng, joalo ka li-gear housings, lihlooho tsa li-cylinder, lithupa tse kopanyang, le matsoho a lever.

Ts'ebetso ea ho lahla hlobo ea shell e na le mehato e latelang:

- Tlhahiso ea mohlala- Paterone ea likotoana tse peli tsa tšepe e entsoe ka sebopeho sa karolo e lakatsehang, hangata ho tloha ho tšepe kapa tšepe. Ka linako tse ling ho sebelisoa lisebelisoa tse ling, joalo ka aluminium bakeng sa tlhahiso ea molumo o tlase kapa graphite bakeng sa ho etsa lisebelisoa tse sebetsang.

- Popo ea hlobo- Ntlha ea pele, halofo ea mohlala e 'ngoe le e' ngoe e futhumetse ho 175-370 ° C (350-700 ° F) 'me e koahetsoe ka lubricant ho nolofalletsa ho tlosoa. Ka mor'a moo, mohlala o futhumetseng o tlamelloa ka lebokoseng la ho lahlela, le nang le motsoako oa lehlabathe le se kopanyang resin. Lebokose la ho lahlela le khelohile, e leng se lumellang motsoako ona oa lehlabathe hore o tlose mohlala. Mokhoa o futhumetseng o phekola motsoako, oo joale o etsang khetla ho pota-pota mohlala. Karolo e 'ngoe le e' ngoe ea mohlala le khetla e potolohileng e phekoleha ho phethoa ka ontong ebe khetla e ntšoa ho tloha pateroneng.

- Kopano ea hlobo- Lihalofo tse peli tsa likhetla li kopantsoe hammoho 'me li tlanngoe ka mokhoa o sireletsehileng ho etsa hlobo e felletseng ea khetla. Haeba ho na le li-cores tse hlokahalang, li kenngoa pele ho koala hlobo. Ka mor'a moo, hlobo e kenngoa ka har'a botlolo ebe e tšehetsoa ka lesela le tšehelitsoeng.

- Ho tshela- Mouta o tlameletsoe hammoho ka mokhoa o sireletsehileng ha tšepe e qhibilihisitsoeng e tšeloa ho tloha ka ladle ho kena ka har'a lekhalo 'me e tlatsa lesoba la hlobo.

- Ho phodisa- Ka mor'a hore hlobo e tlatsitsoe, tšepe e qhibilihisitsoeng e lumelloa ho pholile le ho tiisa sebopeho sa ho lahla ho qetela.

- Ho lahla- Ka mor'a hore tšepe e qhibilihisitsoeng e pholile, hlobo e ka robeha 'me ea tlosoa. Ho hlokahala mekhoa ea ho kuta le ho hloekisa ho tlosa tšepe leha e le efe e feteletseng tsamaisong ea lijo le lehlabathe leha e le lefe le tsoang hlobo.

Tsebo

| ||||||||||||||||||||||||||||||||||||