Inkqubo yokuphosa i-Shell Mold

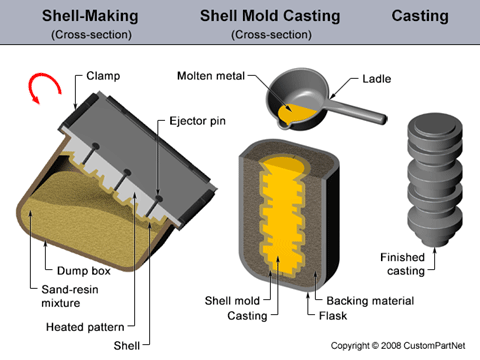

Ukubunjwa kobunjwa beqokobhe yinkqubo yokubunjwa kwentsimbi efana nokugalelwa kwesanti, kweso sinyibilili sigalelwa kumngundo onokusetyenziswa. Nangona kunjalo, ekubunjweni kokungunda kweqokobhe, ukungunda liqokobhe elinodonga olucekethekileyo elenziwe ngokufaka umxube wentlaka yentlabathi ejikeleze ipateni. Ipatheni, isiqwenga sesinyithi esikwimilo yenxalenye efunwayo, iphinda isetyenziswe ukwenza iimolds ezininzi zeqokobhe. Ipateni enokuphinda isetyenziswe ivumela amaxabiso aphezulu emveliso, ngelixa iimolds ezilahlwayo zenza ukuba iijiyometri ezintsonkothileyo ziphoswe. Ukubunjwa kwe-shell mold kufuna ukusetyenziswa kwepateni yentsimbi, i-oven, umxube wesanti-resin, ibhokisi yokulahla, kunye nesinyithi esityhidiweyo.

I-shell mold casting ivumela ukusetyenziswa kwesinyithi kunye ne-non-ferrous metals, ngokuqhelekileyo kusetyenziswa i-iron cast, i-carbon steel, i-alloy steel, i-stainless steel, i-alloys ye-aluminium kunye ne-alloys yobhedu. Iinxalenye eziqhelekileyo zincinci ukuya kuphakathi ngobukhulu kwaye zifuna ukuchaneka okuphezulu, njengezindlu zegiya, iintloko ze-cylinder, iintonga zokudibanisa, kunye neengalo ze-lever.

Inkqubo yokubunjwa kweqokobhe inala manyathelo alandelayo:

- Ukwenziwa kwepateni- Ipateni yentsimbi emibini yenziwe ngendlela yecandelo elifunwayo, ngokuqhelekileyo kwintsimbi okanye intsimbi. Ezinye izinto zisetyenziswa ngamanye amaxesha, njenge-aluminiyam yokuvelisa umthamo ophantsi okanye igraphite yokuphosa izinto ezisebenzayo.

- Ukudala ngundo- Okokuqala, isiqingatha sepateni ngasinye sifudunyezwa kwi-175-370 ° C (350-700 ° F) kwaye sifakwe nge-lubricant ukuze kube lula ukususwa. Emva koko, ipateni efudumeleyo ibotshelelwe kwibhokisi yokulahla, equlethe umxube wesanti kunye ne-resin binder. Ibhokisi yokulahla iguqulwe, ivumela lo mxube wentlaka yentlabathi ukuba ugqume ipateni. Ipateni eshushu iphilisa ngokuyinxenye umxube, ngoku yenza iqokobhe elijikeleze ipateni. Isiqingatha sepateni nganye kunye neqokobhe elijikelezileyo liyanyangwa ukuba ligqitywe kwi-oveni kwaye emva koko iqokobhe likhutshiwe kwipatheni.

- Indibano yokungunda- Iziqingatha ezibini zeqokobhe zidityaniswe kunye kwaye zibotshwe ngokukhuselekileyo ukwenza iqokobhe elipheleleyo lokungunda. Ukuba kukho ii-cores ezifunekayo, zifakwe ngaphambi kokuvala i-mold. Emva koko i-shell mold ifakwa kwi-flask kwaye ixhaswe yinto exhasayo.

- Ukugalela- Umngundo ubambene ngokukhuselekileyo ngelixa isinyithi esinyibilikisiweyo sigalelwa ukusuka kwileyidi ukuya kwindlela yokungena kwaye izalise umngxuma wokungunda.

- Ukupholisa- Emva kokuba i-mold izaliswe, isinyithi esityhidiweyo sivumelekile ukuba sipholile kwaye siqiniswe kwisimo sokugqibela.

- Ukususwa kokuphosa- Emva kokuba intsimbi etyhidiweyo ipholile, i-mold ingaphulwa kwaye i-casting isuswe. Iinkqubo zokunquma kunye nokucoca ziyafuneka ukuba zisuse nayiphi na isinyithi engaphezulu kwi-feed system kunye nayiphi na isanti ephuma kwi-mold.

Izakhono

| ||||||||||||||||||||||||||||||||||||