Iindidi zentsimbi

Iindidi zentsimbi

Esi sahluko siza kuxubusha ngeentlobo ezahlukeneyo zokubunjwa kwentsimbi.

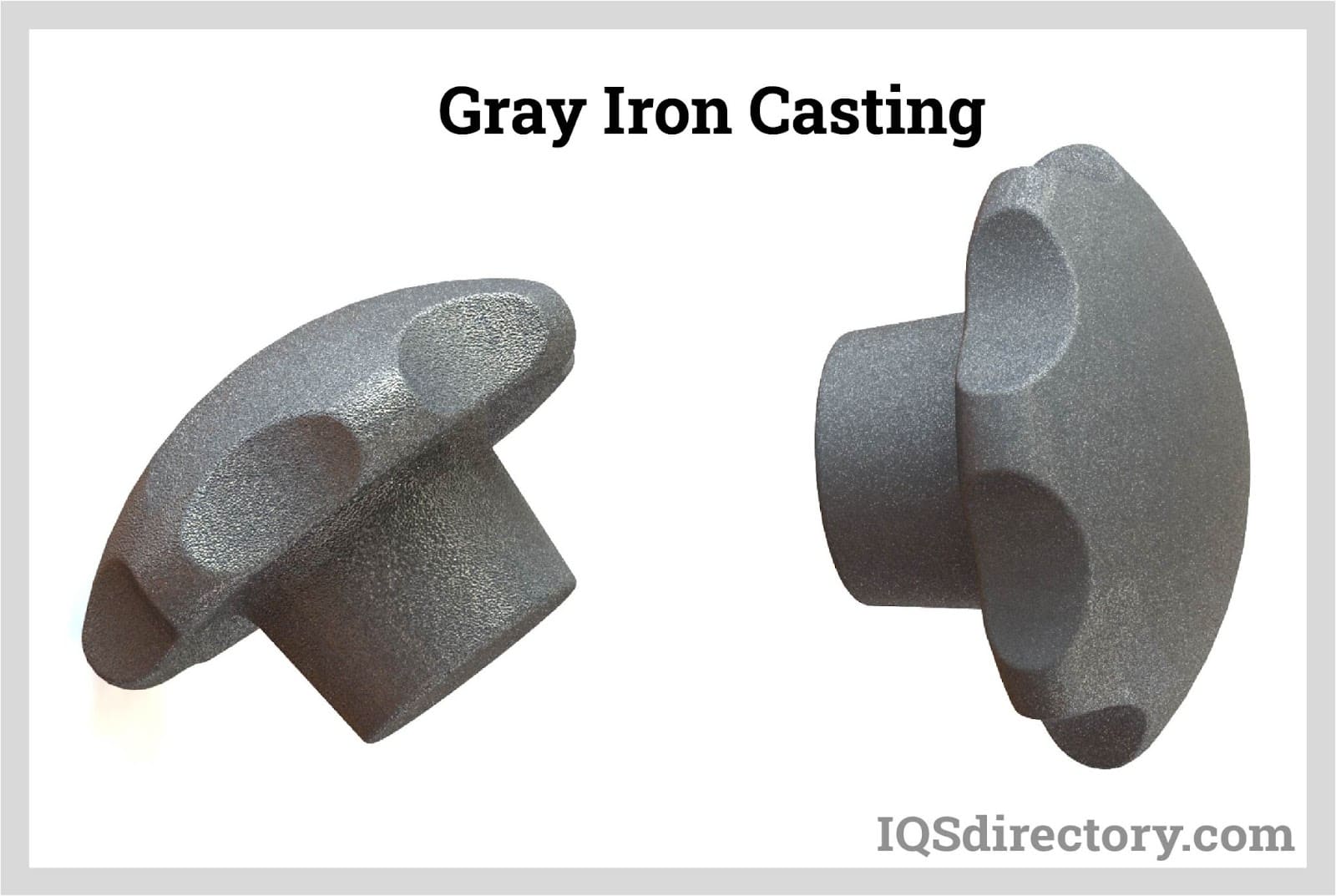

Ukuphoswa kwentsimbi eGrey

Uphawu lwe-grey cast iron yi-graphic microstructure, ekwazi ukubangela i-fractures kwizinto eziphathekayo kwaye ibe nembonakalo engwevu. Olu lolona hlobo luqhelekileyo lusetyenziswayo lwentsimbi etyhidiweyo kunye nezinto ezisetyenziswa ngokuqhelekileyo ezisekelwe kubunzima. Uninzi lweentsimbi ezimpunga zinemichiza ye-2.5 ukuya kwi-4 yeepesenti zekhabhoni, ipesenti ezi-1 ukuya kwi-3 yeepesenti ze-silicone kunye nezinye ziyi-iron.

Olu hlobo lwentsimbi lunamandla amancinci kunye nokuxhatshazwa okuncinci xa kuthelekiswa nentsimbi. Amandla ayo oxinzelelo afaniswa nentsimbi yekhabhoni ephantsi kunye nephakathi.

Zonke ezi zixhobo zoomatshini zilawulwa yimilo ye-graphite flake kunye nobukhulu be-graphite flakes, ekhoyo kwi-microstructure yentsimbi engwevu.

Ukuphoswa kwentsimbi emhlophe

Olu hlobo lwentsimbi lunendawo ezaphukileyo ezimhlophe ngenxa yobukho bentsimbi ye-carbide precipitate ebizwa ngokuba yi-cementite. Ikhabhoni equlethwe kwintsimbi etyhidiweyo emhlophe iphuma kwinyibilika njengoko idibene nesamente yesigaba esizinzileyo kunegraphite. Oku kuphunyezwa ngomxholo wesilicon osezantsi njengearhente yegraphitizing kunye nesantya sokupholisa esibonelelwe ngokukhawuleza. Emva kwesi mvula, i-cementite yenza njengamaqhekeza amakhulu.

Ngexesha lemvula ye-iron carbide, i-precipitate idonsa i-carbon kwi-melt yasekuqaleni, ngaloo ndlela ihambisa umxube ukuya kwenye ekufutshane ne-eutectic. Isigaba esiseleyo kukuthoba isinyithi kwi-carbon austenite, eguqukayo kwi-martensite xa sele ipholile.

Ezi ziqulathe ii-eutectic carbides zinkulu kakhulu ukuba zingabonelela ngenzuzo yokuqina kwemvula. Kwezinye iintsimbi kusenokubakho imvula yesamente encinci kakhulu enokuthi ithwale inguquko yeplastiki ngokuthintela intshukumo yokwahlukaniswa ngematrix yentsimbi ecocekileyo yeferrite. Banenzuzo njengoko benyusa ubulukhuni bentsimbi yentsimbi ngenxa nje yobunzima babo kunye neqhezu lomthamo. Oku kubangela ukuba ubunzima obukhulu bukwazi ukuqikelelwa ngumgaqo wemixube.

Obu bunzima bunikezelwa ngeendleko zobunzima kuyo nayiphi na imeko. Intsimbi emhlophe inokuthi ihlelwe ngokubanzi njengesamente, kuba i-carbide yenza inxalenye enkulu yezinto. I-iron emhlophe i-brittle kakhulu ukuba ingasetyenziswa kumacandelo esakhiwo, kodwa ngenxa yokuqina kwayo okulungileyo, ukuchasana nokukrazula, kunye nexabiso eliphantsi, inokusetyenziswa njengendawo yokunxiba yeempompo ezinodaka.

Kunzima ukupholisa ukujula okungqindilili ngesantya esikhawulezayo esaneleyo ukuqina inyibilika njengentsimbi etyhidiweyo emhlophe, nangona kunjalo ukupholisa ngokukhawuleza kunokusetyenziswa ukuze kuqiniswe isihogo sentsimbi emhlophe kwaye emva koku intsalela yayo iya kuba. ziphole ngesantya esicothayo ngaloo ndlela kwakheka umbindi wentsimbi engwevu. Esi siphumo sesamente sibizwa ngokuba yi-chilled casting, kwaye iqulethe izibonelelo zokuba nomphezulu oqinileyo kodwa ngaphakathi oqinileyo.

Ingxubevange yentsimbi emhlophe yechromium ephezulu ibinamandla okuvumela ukujulwa okukhulu okumalunga neetoni ezili-10 zokwenziwa kwesanti. Oku kungenxa yokuba ichromium inciphisa izinga lokupholisa elifunekayo ukuvelisa i-carbides ngobunzima obukhulu bezinto. IiCarbides ezinokumelana okugqwesileyo kwe-abrasion nazo ziveliswa zizinto zechromium.

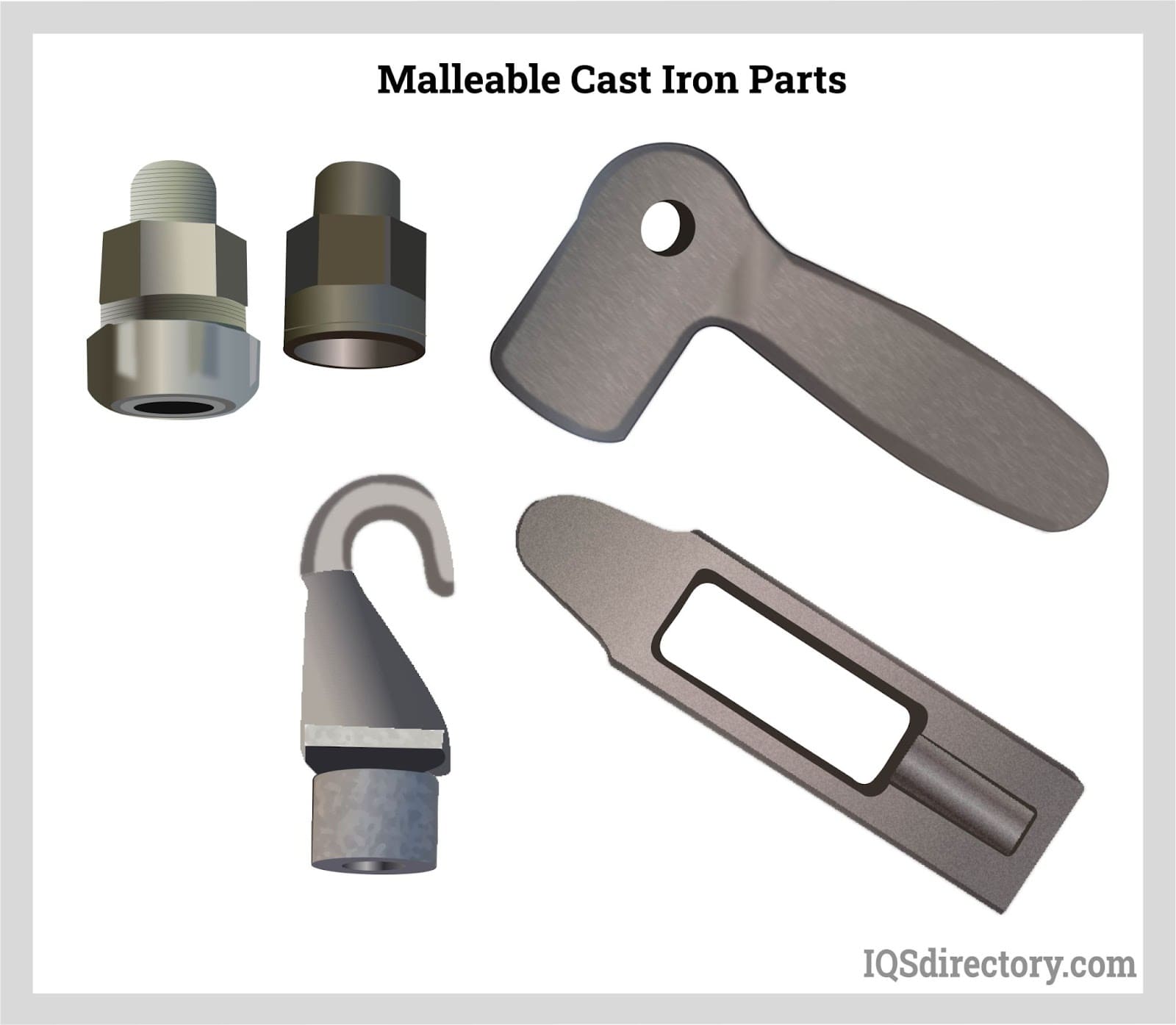

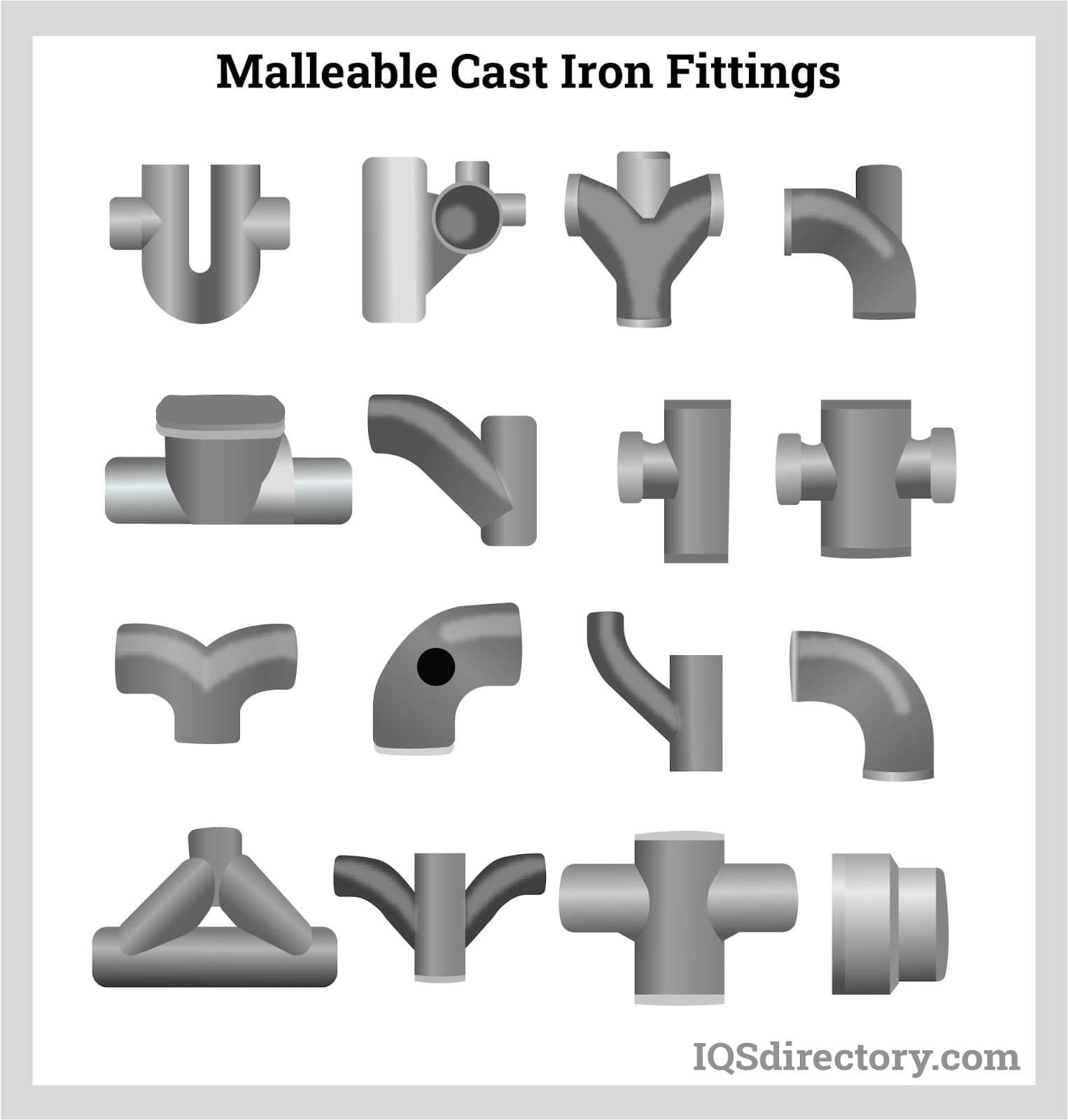

Ukuphosa intsimbi eMalleable

Intsimbi ethambileyo etyhidiweyo iqala njengokugalelwa kwentsimbi emhlophe, emva koko ubushushu buphathwe kumaqondo obushushu obumalunga nama-950°C kangangeentsuku ezimbini okanye olunye, emva koko bupholiswe kwangelo xesha linye.

Ikhabhoni kwi-iron carbide emva koko iguquka ibe yigraphite kunye neferrite kunye nekhabhoni ngenxa yale nkqubo yokufudumeza kunye nokupholisa. Le yinkqubo ephantsi, kodwa yenza ukuba ukutsalwa komphezulu kuguqule igraphite ibe ngamasuntswana angqukuva kuneflakes.

I-spheroids imfutshane kwaye ikude enye kwenye ngenxa yomlinganiselo wabo ophantsi. Kwakhona ziqulethe i-cross-section ephantsi, i-propagation crack kunye ne-photon. Ngokuchaseneyo neeflakes, zinemida engacacanga ethatha inxaxheba ekudambiseni iingxaki zokuxinana koxinzelelo ezifumaneka kwintsimbi engwevu. Lilonke, iipropathi ezibandakanyiweyo kwintsimbi ekhatywayo ethambileyo zifana nezo zentsimbi ezinobulali ngokwendalo.

I-Ductile Iron Casting

Ngamanye amaxesha kuthiwa yi-nodular cast iron, le ntsimbi yentsimbi inegraphite yayo ekwimo yamaqhuqhuva amancinci kakhulu, kunye negraphite inohlobo lweeleya ezixineneyo kwaye zenza amaqhuqhuva. Ngenxa yoku, iipropati zei-ductile cast ironzezentsimbi eziponji ezingenazo iziphumo zoxinzelelo loxinzelelo eziveliswa ziiflakes zegraphite.

Isixa se-carbon concentration equlethwe malunga neepesenti ezi-3 ukuya kwi-4 ekhulwini, kwaye i-silicon ijikeleze ipesenti ze-1.8 ukuya kwi-2.8 ekhulwini. Izixa ezincinci ze-0.02 ukuya kwi-0.1 yeepesenti ze-magnesium, kwaye kuphela i-0.02 ipesenti ukuya kwi-0.04 yepesenti ye-cerium xa idityaniswe kwezi ngxubevange ithoba isantya sokukhula kwemvula yegraphite ngokudibanisa kwimiphetho yeendlela zegraphite.

Ikhabhoni inokuba nethuba lokwahlula njengamasuntswana angama-spheroidal njengoko izinto ziqina, ngenxa yokulawulwa ngononophelo kwezinye izinto kunye nexesha elifanelekileyo ngexesha lenkqubo. Iingqungquthela ezibangelwayo zifana nentsimbi edibeneyo, kodwa iinxalenye zinokuphoswa ngamacandelo amakhulu.

Alloying Elements

Iipropati zentsimbi etyhidiweyo zitshintshwa kwaye zongezwa kwizinto ezahlukeneyo zokudibanisa okanye i-alloyants kwintsimbi. Ngokuhambelana nekhabhoni yi-silicon element kuba inamandla okunyanzela ikhabhoni ngaphandle kwesisombululo. Ipesenti encinci ye-silicon ayinakukwazi ukufezekisa ngokupheleleyo oku njengoko ivumela ukuba ikhabhoni ihlale kwisisombululo, ngaloo ndlela yenza i-iron carbide kwaye ivelise isinyithi esimhlophe.

Ipesenti enkulu okanye ukuxinwa kwe-silicon iyakwazi ukunyanzela ikhabhoni ngaphandle kwesisombululo kwaye yenze igraphite kwaye ivelise intsimbi engwevu. Ezinye i-alloying agents ezingaqatshelwanga ziquka i-manganese, i-chromium, i-titanium kunye ne-vanadium. Ezi zichasene ne-silicon, zikwakhuthaza ukugcinwa kwekhabhoni kwaye ngaloo ndlela kwakheka kwee-carbides. I-Nickel kunye ne-element copper ine-advanteji njengoko ikhulisa amandla kunye nokunyanzeliswa, kodwa ayikwazi ukutshintsha inani lekhabhoni eyenziwe.

Ikhabhoni ekwimo ye-graphite iphumela kwintsimbi ethambileyo, ngaloo ndlela inciphisa umphumo wokuncipha, ukunciphisa amandla kunye nokunciphisa ubuninzi obuqulethweyo. Isulfure sisingcolisi xa iqulathiweyo, kwaye yenza i-iron sulfide ethintela ukwakheka kwegraphite kwaye enyusa ubulukhuni.

Ububi obubekwe yisulfure kukuba yenza i-viscous yentsimbi etyhidiweyo, ebangela iziphene. Ukubonelela kunye nokuphelisa imiphumo yesulfure, i-manganese yongezwa kwisisombululo. Oku kwenziwa kuba xa ezi zimbini zidityanisiwe zenza imanganese sulfide endaweni ye-iron sulfide. Isiphumo semanganese sulfide ikhaphukhaphu kunenyibiliko kwaye ithande ukudada ngaphandle kokunyibilika kwaye ingene kwi-slag.

Uqikelelo lwemali yemanganese efunekayo ukucinywa kweziphumo zesulfure yi-1.7 yeeyunithi zesiqulatho sesulfure kunye ne-0.3 yepesenti eyongezelelweyo yongezwa ngaphezulu. Ukongezwa okungaphezulu kwesi sixa semanganese kubangela ukubunjwa kwe-manganese carbide kwaye oku kwandisa ubulukhuni kunye nokubandayo ngaphandle kwe-iron engwevu apho ukuya kwi-1 ekhulwini ye-manganese inokunyusa amandla kunye noxinaniso oluqulethwe. I-Nickel yenye yezona zinto ziqhelekileyo zokuhlanganisa i-alloying ngenxa yokuba inomkhuba wokucoca i-pearlite kunye nesakhiwo segraphite, ngaloo ndlela iphucula ukuqina, kwaye idibanisa ukuhlukana kobunzima phakathi kobunzima becandelo.

I-Chromium yongezwa ngamanani amancinci ukunciphisa igraphite yamahhala kwaye ivelise ukubandayo. Oku kungenxa yokuba i-chromium yi-carbide stabilizer enamandla, kwaye kwezinye iimeko inokusebenza ngokubambisana ne-nickel. Kwichromium kwakhona, indawo encinci yetoti inokongezwa. I-Copper yongezwa kwi-ladle okanye kwisithando somlilo ngomyalelo we-0.5 ekhulwini ukuya kwi-2.5 yeepesenti ukufezekisa ukuhla kwe-chill, ukucocwa kwegraphite, kunye nokunyuka kwe-fluidity. I-molybdenum nayo inokongezwa ngokomyalelo we-0.3 yeepesenti ukuya kwi-1 yepesenti ukuze kwandiswe i-chill, ukucokisa i-graphite, kunye nokucokisa isakhiwo se-pearlite.

Ngokuqhelekileyo yongezwa ngokusebenza ngokuhambelana ne-nickel, ubhedu, kunye ne-chromium ukuvelisa iintsimbi ezinamandla. I-element titanium yongezwa ukuba isebenze njenge-degasser kunye ne-deoxidizer, kunye nokwandisa umbane. Ubungakanani beepesenti ze-0.15 ukuya kwi-0.5 yeepesenti ze-element vanadium zongezwa kwintsimbi etyhidiweyo kunye nokunceda ukuzinzisa i-cementite, ukunyusa ukuqina kunye nokuchasana nokugqoka kunye nokushisa.

I-Zirconium inceda ukwenza i-graphite kwaye yongezwa ngokulinganayo malunga neepesenti ze-0.1 ukuya kwi-0.3 ekhulwini. Esi siqalelo sikwanceda kwi-deoxidizing kunye nokwandisa ubumanzi. Kwizinto ezinyibilikayo zesinyithi ezinyibilikayo, ukuze kwandiswe ingakanani i-silicon enokongezwa, i-bismuth igalelwa kwisikali se-0.002 ukuya kwi-0.01 ekhulwini. Kwintsimbi emhlophe, i-elementi ye-boron yongezwa, enceda ekuveliseni intsimbi ethambileyo, kwaye inciphisa impembelelo erhabaxa yebismuth.