Inqubo Yokusakaza Isikhunta seShell

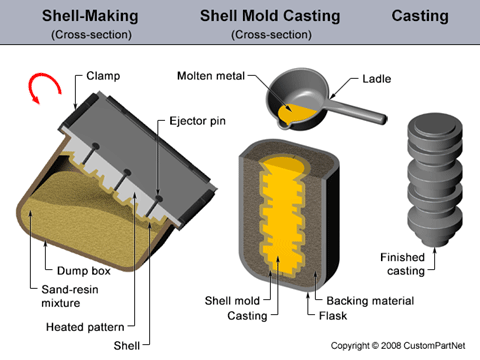

Ukubunjwa kwe-shell mold kuyinqubo yokubunjwa kwensimbi efana nokubunjwa kwesihlabathi, kuleyo nsimbi encibilikisiwe ithululelwa esikhunjini esisebenziseka kalula. Nokho, ekubunjweni kwesikhunta segobolondo, isikhunta siyigobolondo elinezindonga ezincane elakhiwe ngokufaka ingxube yenhlaka yesihlabathi ezungeze iphethini. Iphethini, ucezu lwensimbi olusesimweni sengxenye efunwayo, luphinde lusetshenziswe ukwakha isikhunta samagobolondo amaningi. Iphethini engase isetshenziswe kabusha ivumela amazinga aphezulu okukhiqiza, kuyilapho isikhunta esilahlwayo sivumela amajiyometri ayinkimbinkimbi ukuthi asakazwe. Ukubunjwa kwesikhunta segobolondo kudinga ukusetshenziswa kwephethini yensimbi, ihhavini, ingxube ye-sand-resin, ibhokisi lokulahla, nensimbi encibilikisiwe.

Ukubunjwa kwesikhunta seShell kuvumela ukusetshenziswa kokubili kwensimbi eyinsimbi nezingezona ayoni, ngokuvamile kusetshenziswa i-cast iron, carbon steel, i-alloy steel, insimbi engagqwali, ama-alloys e-aluminium, nama-alloys ethusi. Izingxenye ezijwayelekile zinosayizi omncane ukuya-maphakathi futhi zidinga ukunemba okuphezulu, njengezindlu zamagiya, amakhanda amasilinda, izinti zokuxhuma, nezingalo zokuleva.

Inqubo ye-shell mold casting iqukethe izinyathelo ezilandelayo:

- Ukudalwa kwephethini- Iphethini yensimbi enezicucu ezimbili yenziwa ngesimo sengxenye oyifunayo, ngokuvamile isuka kunsimbi noma insimbi. Ezinye izinto ezisetshenziswayo kwesinye isikhathi ziyasetshenziswa, njenge-aluminium yokukhiqiza ivolumu ephansi noma i-graphite yokuphonsa izinto ezisebenzayo.

- Ukudala isikhunta- Okokuqala, uhhafu wephethini ngayinye ushisiswe ku-175-370 ° C (350-700 ° F) futhi umbozwe nge-lubricant ukuze kube lula ukususwa. Okulandelayo, iphethini eshisayo iboshelwa ebhokisini lokulahla, eliqukethe ingxube yesihlabathi kanye ne-resin binder. Ibhokisi lokulahla lihlanekezelwe, okuvumela le ngxube ye-sand-resin ukuthi igqoke iphethini. Iphethini eshisayo ilapha ingxenye, manje eyenza igobolondo elizungeze iphethini. Uhhafu wephethini ngayinye kanye negobolondo elizungezile liyelapheka ukuze liqedwe kuhhavini bese igobolondo likhishwa kuphethini.

- Ukuhlanganiswa kwesikhunta- Amahhafu amagobolondo amabili ahlanganiswa ndawonye futhi aboshelwe ngokuvikelekile ukuze enze isikhunta segobolondo esiphelele. Uma kukhona ama-cores adingekayo, afakwa ngaphambi kokuvala isikhunta. Khona-ke isikhunta segobolondo sifakwa eflaskini futhi sisekelwe ngezinto ezisekelayo.

- Ukuthela- Isikhunta siboshelwe ndawonye ngokuvikelekile kuyilapho insimbi encibilikisiwe ithululwa isuka kulayini iye ohlelweni lokungena futhi igcwalise isikhunta.

- Ukupholisa- Ngemva kokuba isikhunta sesigcwalisiwe, insimbi encibilikisiwe ivunyelwe ukupholisa futhi iqine ibe yisimo sokubunjwa kokugcina.

- Ukususwa kokusakaza- Ngemva kokuba insimbi encibilikisiwe isipholile, isikhunta singaphulwa futhi kukhishwe ukubunjwa. Izinqubo zokunquma nokuhlanza ziyadingeka ukuze kukhishwe noma iyiphi insimbi eyeqile ohlelweni lokuphakelayo nanoma yisiphi isihlabathi esibunjweni.

Amakhono

| ||||||||||||||||||||||||||||||||||||