Izinhlobo ze-Iron Castings

Izinhlobo ze-Iron Castings

Lesi sahluko sizoxoxa ngezinhlobo ezahlukene zokubunjwa kwensimbi.

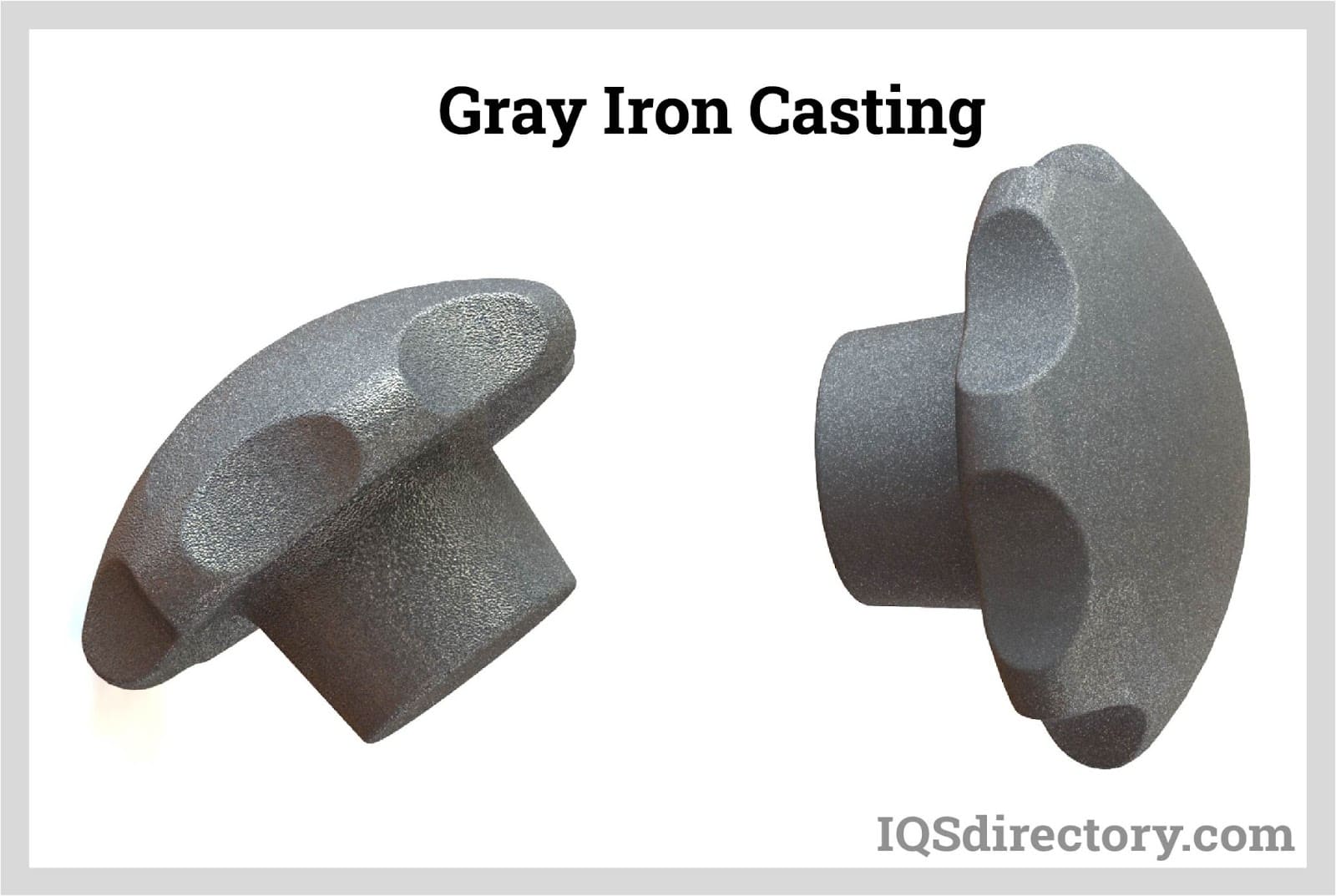

I-Grey Iron Casting

Isici se-grey cast iron yi-graphic microstructure, ekwazi ukubangela ukuphuka kwento futhi ibe nokubukeka okumpunga. Lolu wuhlobo oluvame ukusetshenziswa kakhulu lwensimbi ekhonjiwe futhi olusetshenziswa kakhulu ngezinto ezisansimbi ezisekelwe esisindweni. Iningi lezinsimbi ezimpunga zinokubola kwamakhemikhali okungamaphesenti angu-2.5 kuya kwangu-4 ekhabhoni, amaphesenti angu-1 kuya kumaphesenti angu-3 ama-silicone kanti okunye kuyingxenye yensimbi.

Lolu hlobo lwensimbi ekhonjiwe lunamandla amancane okuqina nokumelana nokushaqeka uma kuqhathaniswa nensimbi. Amandla ayo acindezelayo afaniswa nensimbi ye-carbon steel ephansi naphakathi.

Zonke lezi zici zemishini zilawulwa ukuma kwe-graphite flake kanye nobukhulu bama-graphite flakes, akhona ku-microstructure yensimbi empunga.

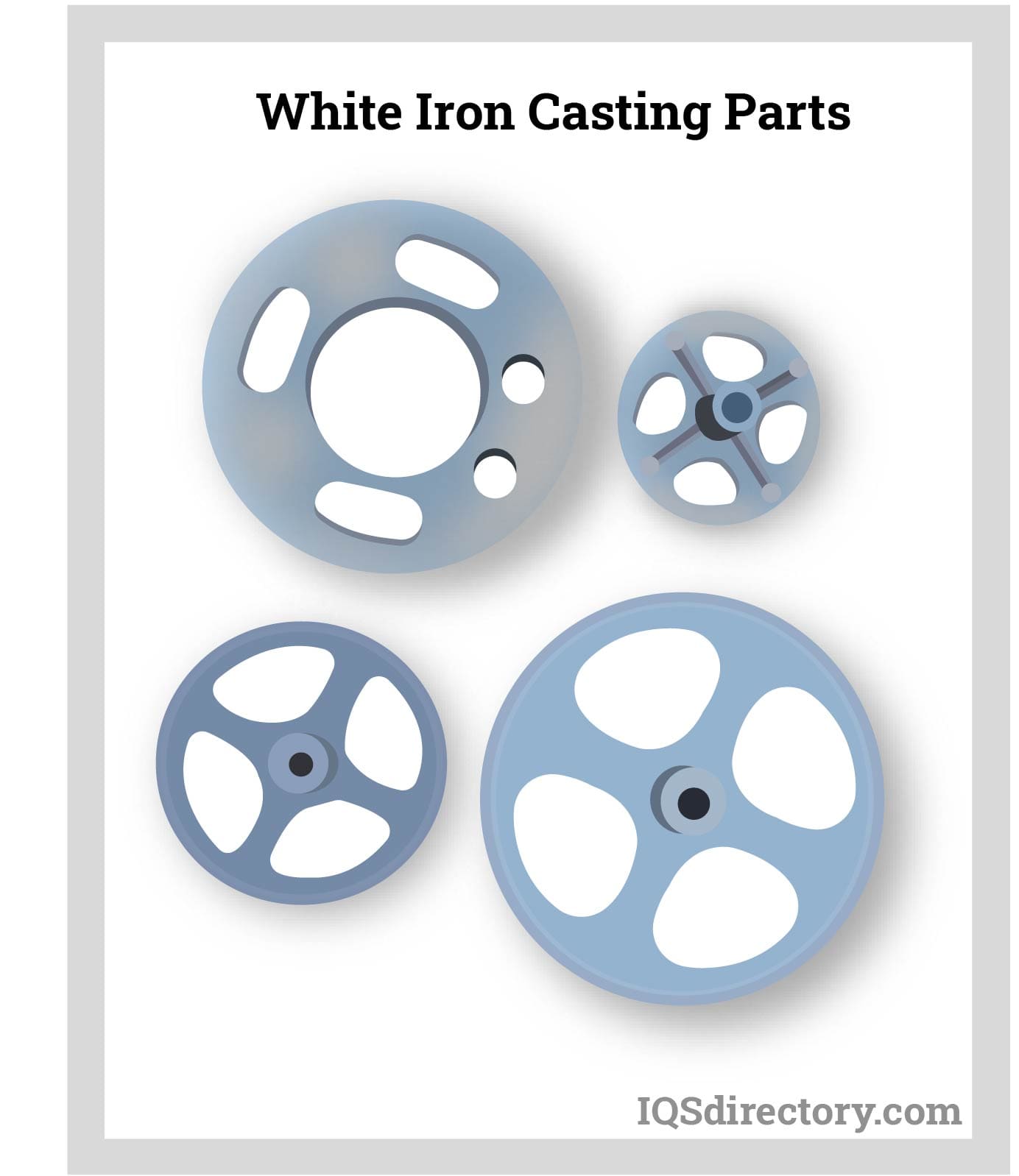

Ukufakwa Kwensimbi Emhlophe

Lolu hlobo lwensimbi lunezindawo eziphukile ezimhlophe ngenxa yokuba khona kwe-iron carbide precipitate ebizwa ngokuthi i-cementite. Ikhabhoni equkethwe ku-iron cast emhlophe iphuma ekuncibilikeni njengoba ihlangene nesigaba esizinzile sikasimende kunokuba ifane negraphite. Lokhu kufinyelelwa ngokuqukethwe kwe-silicon ephansi njenge-ejenti ye-graphitizing kanye nezinga lokupholisa elihlinzekwa ngokushesha. Ngemva kwalokhu kwezulu, i-cementite yakha njengezinhlayiya ezinkulu.

Ngesikhathi sokuna kwe-iron carbide, imvula idonsa ikhabhoni ekuncibilikeni kwasekuqaleni, ngaleyo ndlela ihambise ingxube kuleyo eseduze ne-eutectic. Isigaba esisele ukwehlisa i-iron ku-carbon austenite, eshintsha ibe i-martensite uma isipholile.

Lawa aqukethwe ama-eutectic carbides makhulu kakhulu ukuhlinzeka ngenzuzo yokuqina kwemvula. Kwezinye izinsimbi kungase kube nezimo zensimbi ezincane kakhulu ezingase zithwale ukuguqulwa kwepulasitiki ngokuvimbela ukunyakaza kokuhlukaniswa nge-matrix yensimbi ehlanzekile ye-ferrite. Banenzuzo njengoba bekhulisa ubulukhuni bensimbi ekhonjiwe ngenxa nje yokuqina kwabo kanye nengxenye yevolumu. Lokhu kubangela ukuthi ubulukhuni benqwaba bukwazi ukulinganiselwa ngomthetho wezingxube.

Lobu bunzima bunikezwa ngezindleko zokuqina kunoma yikuphi. I-iron cast emhlophe ingahlukaniswa njengosimende, njengoba i-carbide yenza ingxenye enkulu yento. Insimbi emhlophe ishwabene kakhulu ukuthi ingasetshenziswa ezingxenyeni zesakhiwo, kodwa ngenxa yokuqina kwayo okuhle, ukumelana nokuhuzuka, kanye nezindleko eziphansi, ingasetshenziswa njengendawo egugile yamaphampu anodaka.

Kunzima ukupholisa ukubunjwa okuwugqinsi ngesivinini esisheshayo okwanele ukuqina ukuncibilika njengensimbi ewugqinsi emhlophe, nokho ukupholisa ngokushesha kungasetshenziswa ukuze kuqiniswe isihogo sensimbi emhlophe futhi ngemva kwalokhu insalela yayo izoba. kuphole ngesivinini esincane ngaleyo ndlela kwakha umnyombo wensimbi empunga. Lo mlingisi owumphumela ubizwa ngokuthi ukulingisa okupholile, futhi uqukethe izinzuzo zokuba nendawo eqinile kodwa enengaphakathi eliqinile.

Ama-alloys ensimbi amhlophe e-chromium aphezulu abe nekhono lokuvumela ukusakaza okukhulu okungaba yi-impeller engamathani ayi-10 ukuthi kube ukubunjwa kwesihlabathi. Lokhu kungenxa yokuthi i-chromium yehlisa izinga lokupholisa elidingekayo ukuze kukhiqizwe ama-carbides ngokuqina okukhulu kwempahla. I-Carbides enokumelana okuhle kakhulu kwe-abrasion nayo ikhiqizwa izakhi ze-chromium.

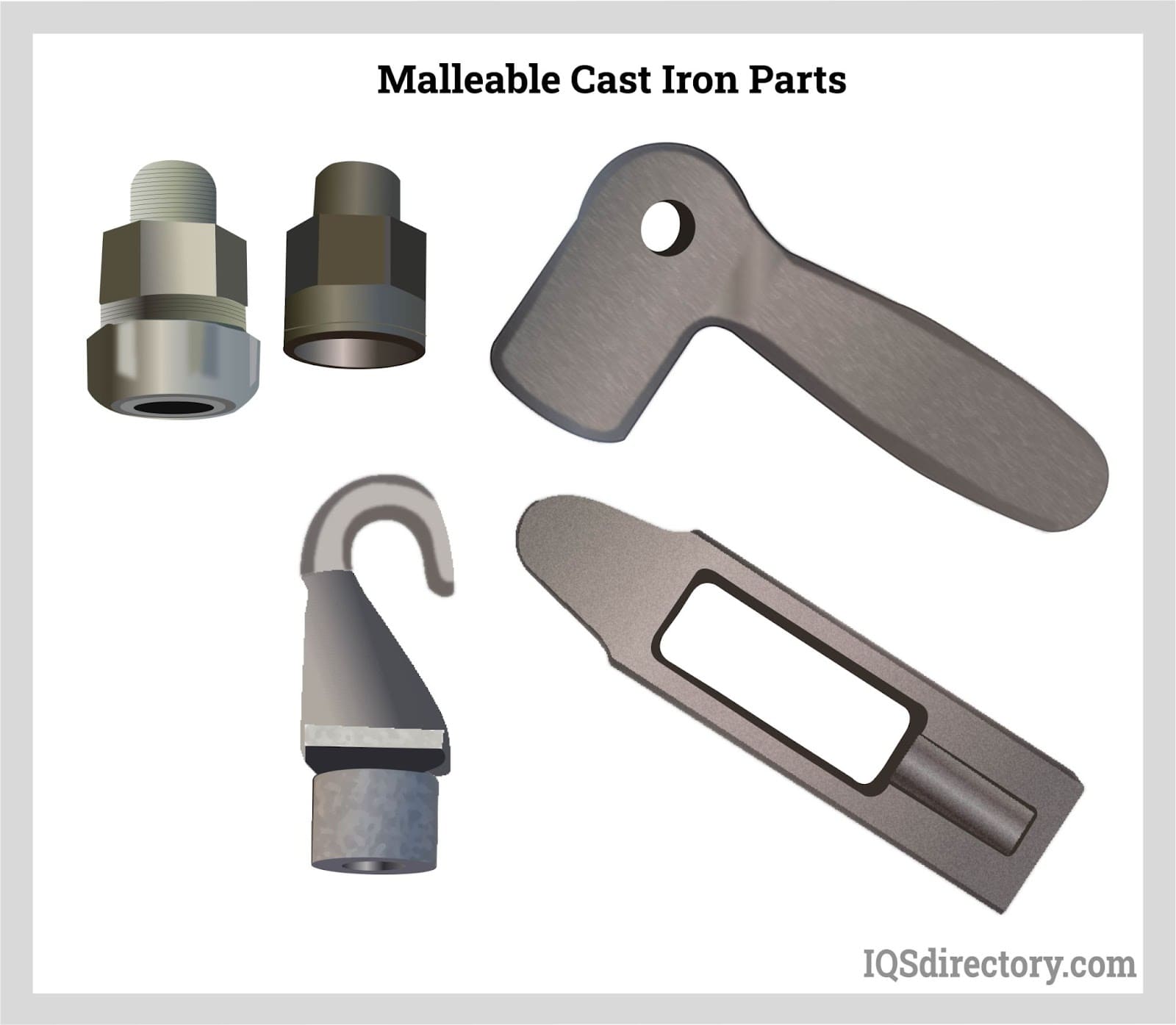

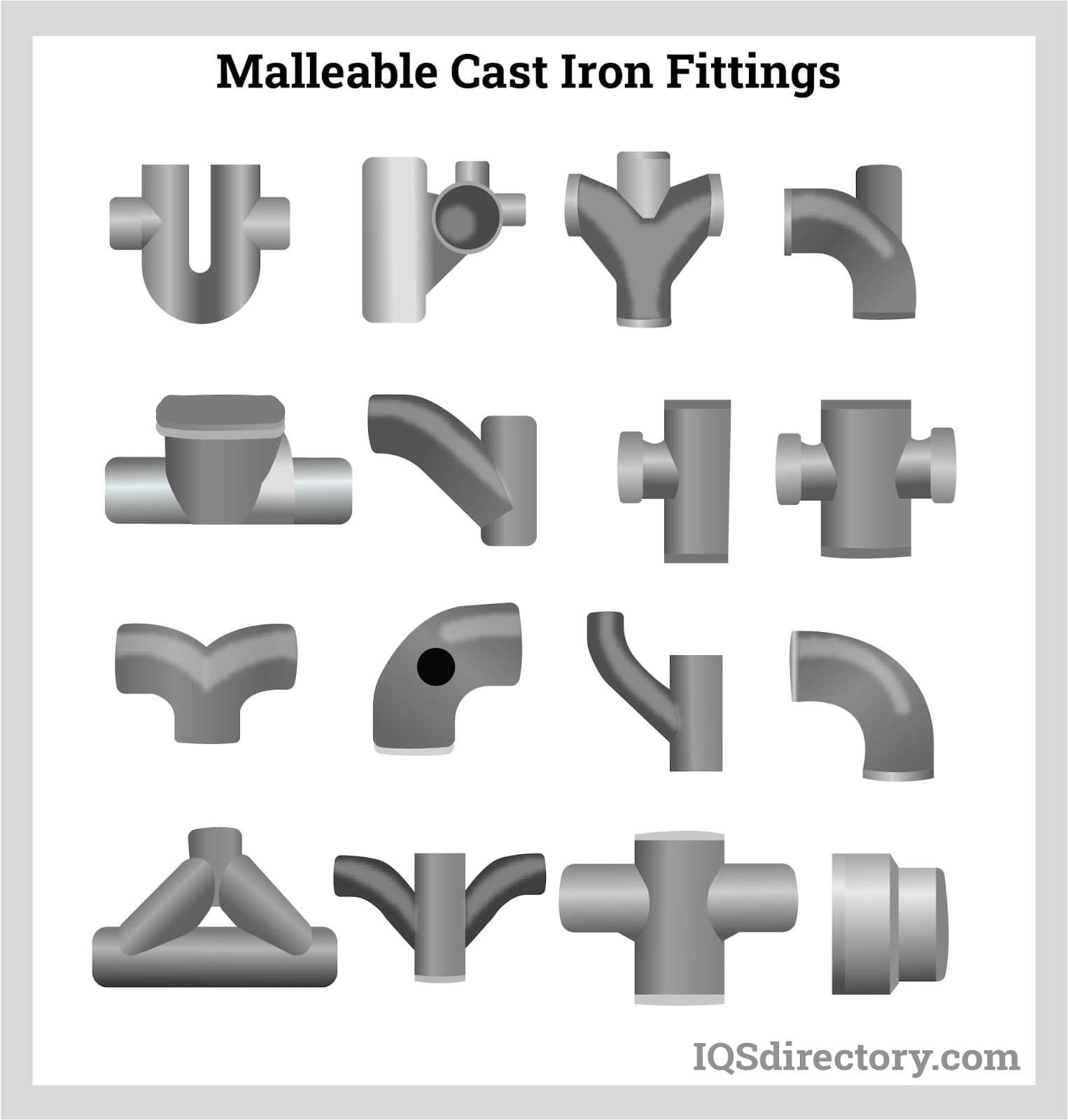

I-Iron Casting engenakulinganiswa

Insimbi exutshwe nensimbi ethambile iqala njengensimbi emhlophe, bese iphathwa ngokushisa emazingeni okushisa angaba ngu-950°C izinsuku ezimbili noma olulodwa, bese ipholiswa ngesikhathi esifanayo.

Ikhabhoni eku-iron carbide bese ishintsha ibe igraphite ne-ferrite plus carbon ngenxa yale nqubo yokushisisa nokupholisa. Lena inqubo ephansi, kodwa yenza ukungezwani okungaphezulu kuguqule i-graphite ibe yizinhlayiya eziyindilinga esikhundleni sama-flakes.

Ama-spheroid mafushane futhi aqhelelene kakhulu namanye ngenxa ye-aspect ratio yawo ephansi. Futhi aqukethe i-cross-section ephansi, ukuqhekeka okusabalalisa kanye ne-photon. Ngokuphambene nama-flakes, aqukethe imingcele engacacile ebamba iqhaza ekwehliseni izinkinga zokugxilisa ingqondo ezitholakala ku-iron grey cast. Sekukonke, izakhiwo ezifakwe ensimbini ethambile ethambile zifana nalezo zensimbi ezithambile ngemvelo.

I-Ductile Iron Casting

Ngezinye izikhathi ibizwa ngokuthi i-nodular cast iron, le iron iron ine-graphite yayo esesimweni samaqhuqhuva amancane kakhulu, igraphite inohlobo lwezingqimba ezigxile futhi ngaleyo ndlela yakhe amaqhuqhuva. Ngenxa yalokhu, izakhiwo zei-ductile cast ironyileyo yensimbi eyisiponji engenazo imiphumela yokugxilisa ingqondo yokucindezeleka ekhiqizwa ama-flakes e-graphite.

Inani lokuhlushwa kwekhabhoni eliqukethwe licishe libe ngamaphesenti ama-3 kuye kwangama-4, kanti lelo le-silicon licishe libe ngamaphesenti angu-1.8 kuya kumaphesenti angu-2.8. Amanani amancane amaphesenti angu-0.02 kuya kumaphesenti angu-0.1 e-magnesium, futhi kuphela amaphesenti angu-0.02 kuya kumaphesenti angu-0.04 kuphela i-cerium lapho engezwa kulawa mangxubevange ehlisa izinga lokukhula kwemvula ye-graphite ngokuhlangana emaphethelweni emizila ye-graphite.

Ikhabhoni ingaba nethuba lokuhlukanisa njengezinhlayiya eziyindilinga njengoba into iqina, ngenxa yokulawula ngokucophelela ezinye izakhi kanye nesikhathi esifanele phakathi nenqubo. Izinhlayiya eziwumphumela zifana ne-cast cast iron ephathekayo, kodwa izingxenye zingaphonswa ngezigaba ezinkulu.

Izinto ze-alloying

Izakhiwo ze-cast iron ziyashintshwa futhi zengezwe ezintweni ezihlukahlukene ze-alloying noma ama-alloyants ensimbi ekhonjiwe. Ngokuhambisana nekhabhoni i-element silicon ngoba inamandla okuphoqa ikhabhoni ukuthi iphume esixazululweni. Iphesenti elincane le-silicon alikwazi ukufeza lokhu ngokugcwele njengoba livumela i-carbon ukuthi ihlale esixazululweni, ngaleyo ndlela yakhe i-iron carbide futhi iphinde ikhiqize i-iron cast iron.

Iphesenti elikhulu noma ukuhlangana kwe-silicon liyakwazi ukukhipha ikhabhoni esixazululweni bese lenza i-graphite futhi likhiqize insimbi empunga. Amanye ama-alloying agents angaziwa ahlanganisa i-manganese, i-chromium, i-titanium bese kuba i-vanadium. Lezi ziphikisana ne-silicon, ziphinde zikhuthaze ukugcinwa kwekhabhoni futhi ngaleyo ndlela futhi ukwakheka kwama-carbides. I-Nickel kanye ne-elementi yethusi kunenzuzo njengoba kwandisa amandla nokuqina, kodwa azikwazi ukushintsha inani lekhabhoni elakhiwe.

Ikhabhoni esesimweni se-graphite iphumela ekubeni yinsimbi ethambile, ngaleyo ndlela inciphise umphumela wokuncipha, inciphise amandla futhi inciphise ukuminyana okuqukethwe. Isibabule ngokuvamile singcolisa uma siqukethwe, futhi sakha i-iron sulfide evimbela ukwakheka kwe-graphite futhi ekhulisa ubulukhuni.

Ububi obubekwa isulfure ukuthi yenza i-viscous yensimbi encibilikisiwe, edala ukukhubazeka. Ukuhlinzeka nokuqeda imiphumela yesulfure, i-manganese yengezwa kwisixazululo. Lokhu kwenziwa ngoba uma lezi zimbili sezihlangene zakha i-manganese sulfide esikhundleni se-iron sulfide. I-manganese sulfide eholelayo ilula kunokuncibilika futhi ijwayele ukuntanta iphume ekuncibilikeni futhi ingene ku-slag.

Inani elilinganiselwe le-manganese elidingekayo ukuze kukhanselwe imiphumela yesibabule amayunithi angu-1.7 wokuqukethwe kwesulfure kanye nengxenye eyengeziwe engu-0.3% engezwe ngaphezulu. Ukwengezwa okungaphezu kwaleli nani le-manganese kubangela ukwakheka kwe-manganese carbide futhi lokhu kwandisa ubulukhuni nokugodola ngaphandle kwensimbi empunga lapho kufika kumaphesenti angu-1 we-manganese engandisa amandla kanye nokuminyana okuqukethwe. I-Nickel ingenye yezinto ezivame kakhulu ze-alloying ngoba inomkhuba wokuhlanza i-pearlite kanye nesakhiwo se-graphite, ngaleyo ndlela ithuthukise ukuqina, futhi ihlukanise umehluko wobunzima phakathi kobukhulu besigaba.

I-Chromium yengezwa ngamanani amancane ukuze kwehliswe i-graphite yamahhala futhi kukhiqizwe ukugodola. Lokhu kungenxa yokuthi i-chromium iyi-carbide stabilizer enamandla, futhi kwezinye izimo ingasebenza ngokubambisana ne-nickel. Ku-chromium futhi, inani elincane lokuthatha indawo yethini lingengezwa. I-Copper yengezwa ku-ladle noma esithandweni ngohlelo lwamaphesenti angu-0.5 kuya kumaphesenti angu-2.5 ukuze kutholwe ukubandayo okuphansi, ukucwenga i-graphite, kanye nokwenyuka koketshezi. I-Molybdenum nayo ingangezwa ngohlelo lwamaphesenti angu-0.3 kuya kumaphesenti angu-1 ukuze futhi kwandiswe ukubandayo, kucwengisiswe i-graphite, futhi kucwengisiswe isakhiwo se-pearlite.

Ivamise ukungezwa ngokusebenza ngokuhambisana ne-nickel, ithusi, ne-chromium ukuze kukhiqizwe ama-ayina anamandla aphezulu. I-elementi ye-titanium yengezwa ukuze isebenze njenge-degasser ne-deoxidizer, futhi ikhulise uketshezi. Izilinganiso zamaphesenti angu-0.15 kuya kumaphesenti angu-0.5 we-elementi ye-vanadium zengezwa kunsimbi ekhonjiwe futhi zisiza ekuqiniseni usimende, ukwandisa ubulukhuni nokumelana nokugqoka nokushisa.

I-Zirconium isiza ukwakha i-graphite futhi yengezwa ngezilinganiso ezingaba ngamaphesenti angu-0.1 kuya kumaphesenti angu-0.3. Lesi sakhi siphinde sisize ekwenzeni i-deoxidizing nokwandisa uketshezi. Ekuncibilikeni kwensimbi ethambileyo, ukuze kwandiswe ukuthi ingakanani i-silicon enganezelwa, i-bismuth ithululwa esikalini samaphesenti angu-0,002 kuya kumaphesenti angu-0.01. Ngensimbi emhlophe, i-elementi ye-boron yengezwa, esiza ekukhiqizeni i-iron ethambile, futhi yehlisa umthelela wokuqina we-bismuth element.